Can using a Filter Press reduce energy consumption and operating costs?

2025.06.09

2025.06.09

Industry News

Industry News

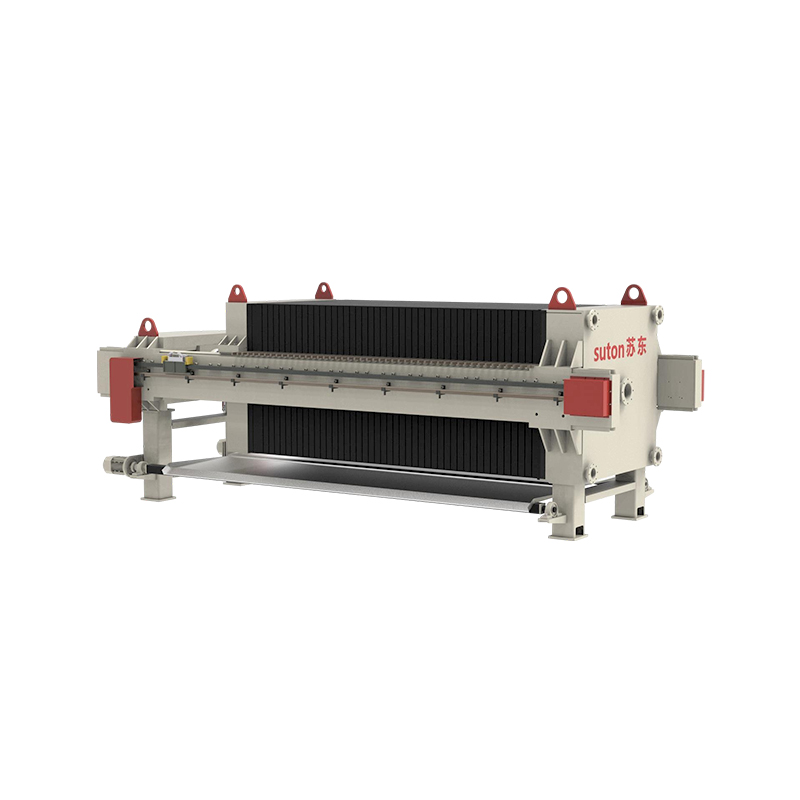

The use of filter presses does have significant potential to reduce energy consumption and operating costs, mainly reflected in its efficient filtration performance and optimized operation process. The high performance of filter presses in solid-liquid separation makes it an ideal choice for treating wastewater and other liquids. Compared with other equipment that requires high energy consumption (such as centrifuges, vacuum filters, etc.), filter presses can complete the separation of solids and liquids with lower energy consumption. When using filter presses, enterprises can not only reduce energy expenses, but also improve the overall efficiency of the treatment process, thereby achieving the goal of energy saving and consumption reduction.

Modern filter presses are usually equipped with highly automated functions such as automatic feeding, automatic filter pressing and automatic slag discharge. These automated features reduce the need for manual intervention, which not only effectively reduces labor costs, but also significantly reduces the risk of operating errors and improper operation. Automated operation also improves the operational stability and consistency of the equipment, so that operators do not need to adjust the equipment frequently, thereby reducing the time and labor costs associated with equipment commissioning and operation.

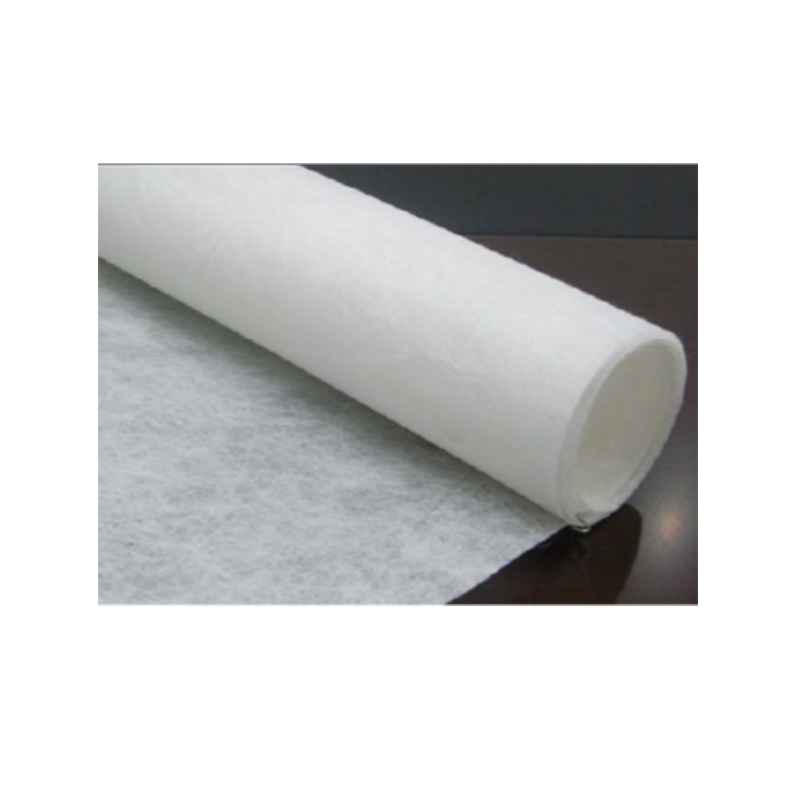

The high filtration efficiency of filter presses means that the service life of its filter cloth is relatively long. In traditional filtration equipment, the filter cloth needs to be replaced frequently, while filter presses reduce the frequency of filter cloth replacement through its optimized design. This not only reduces the purchase cost of the filter cloth, but also greatly reduces the frequency of cleaning and maintenance. The probability of failure during equipment operation is reduced, and downtime caused by equipment damage is reduced, thus saving the related costs of maintenance and repair.

The Filter Press can also remove solid matter from the liquid to the greatest extent during the filtration process, which reduces the need for water and chemicals in the subsequent treatment process. Chemicals and water are inevitable consumables in many industrial processes, and the high-efficiency filtration function of the Filter Press helps to reduce the use of these resources, thereby achieving significant cost savings in long-term operation.

The high processing capacity of the Filter Press is also a key factor in its cost reduction. It can process more materials per unit time, thereby shortening the processing cycle and improving overall production efficiency. By shortening the time for each batch of processing, the company can complete more work in the same time, further reducing the cost per unit of processing.

The design concept of the Filter Press gives it a long service life and less downtime. Due to the strong stability of the equipment, it can maintain efficient operation for a long time, reducing the need for frequent equipment downtime, fault repair and replacement of parts. The stability of the equipment not only improves production efficiency, but also reduces the additional operating costs caused by equipment failure.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt