Why are filter plates a critical component in the high pressure filtration process?

2025.06.16

2025.06.16

Industry News

Industry News

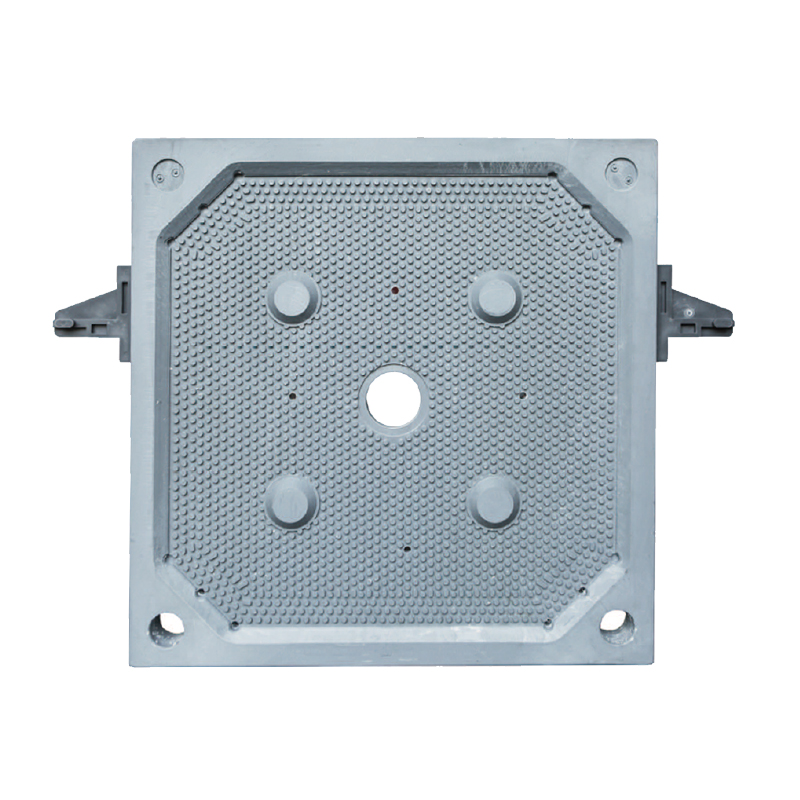

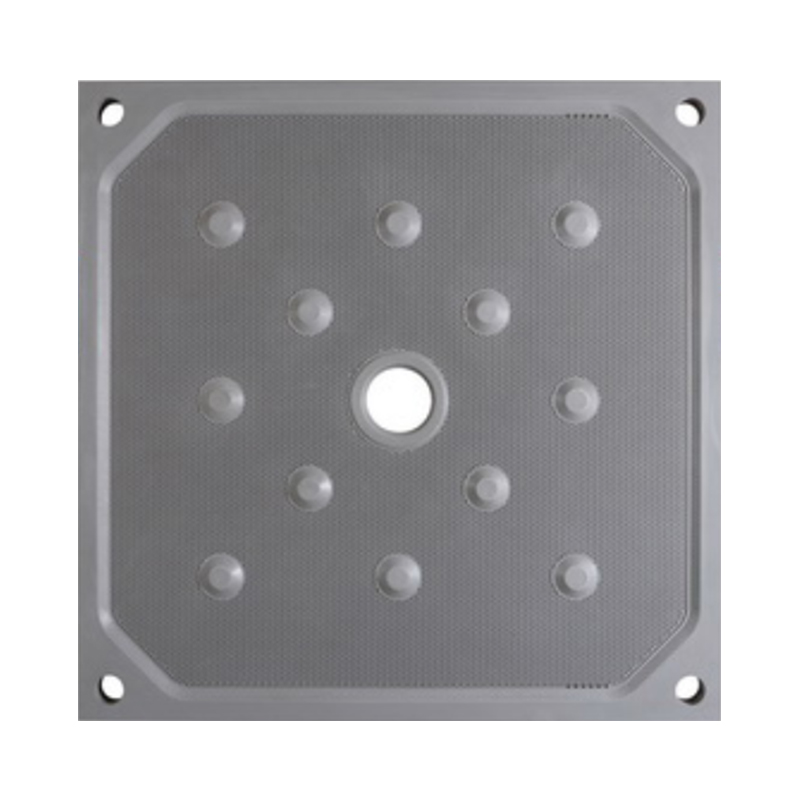

Filter plates play a vital role in the high-pressure filtration process. Their core role is reflected in improving filtration efficiency, withstanding high-pressure operating conditions, optimizing pressure distribution, shortening filtration time, enhancing operational safety, adapting to different material requirements, and reducing maintenance costs.

Filter plates can significantly improve filtration efficiency. In high-pressure filtration systems, the design of the filter plates directly affects the filtration effect. The filter plates can effectively retain solid particles through their precise pore size and structure, while allowing liquid to flow out through the filter cloth. Under high pressure, the uniform pressure distribution provided by the filter plates helps to separate solids and liquids, further improving the efficiency of the filtration process. When handling complex materials, the efficient design of the filter plates ensures that the filtration effect remains stable and accurate even at higher working pressures.

The design of the filter plates enables them to withstand high-pressure operating conditions. During high-pressure filtration, filters often need to withstand pressures of hundreds or even thousands of Pa. In order to adapt to this working environment, filter plates are usually made of high-strength materials, such as steel plates or composite materials, which have extremely strong pressure resistance. They can not only withstand high pressures, but also maintain structural integrity under such extreme conditions to avoid rupture or deformation. Such a design not only improves the stability of the system, but also reduces production downtime caused by equipment failure.

The filter plate also has the function of evenly distributing the filtration pressure during high-pressure filtration. High-pressure filtration requires that the pressure distribution of the entire filtration system must be uniform. Any local pressure that is too high or too low may affect the filtration effect and even cause equipment damage. Through the optimized structural design, the filter plate can effectively and evenly transfer the high pressure to the entire filtration surface, so that each area can be treated consistently, thereby ensuring that the material separation effect during the filtration process is optimal.

During high-pressure filtration, the filter plate can also significantly reduce the filtration time. Under high pressure, liquids can penetrate through the pores of the filter plate more quickly, while solid matter is effectively trapped. This efficient filtration mechanism helps shorten the time of the entire filtration process and improve production efficiency. Especially in industrial production, the reduction in filtration time directly translates into a shortened production cycle, which is of great significance for improving overall production capacity and reducing operating costs.

From a safety perspective, the high-pressure resistance of the filter plate greatly improves the safety of the entire filtration process. Since the filter plate is usually made of corrosion-resistant and wear-resistant materials, it can effectively prevent dangerous situations such as rupture and leakage during high-pressure filtration. This high pressure resistance not only ensures the safety of equipment and materials, but also provides a safer working environment for operators. Especially when dealing with toxic, harmful or high-temperature substances, the stability of the filter plate is crucial to minimize risks.

The adaptability of the filter plate is also one of the reasons why it is a key component in the high-pressure filtration process. Different materials have different physical properties, such as particle size, viscosity and chemical reactivity. The design of the filter plate can be adjusted according to the needs of different materials to ensure the best filtration effect under high pressure conditions. This flexibility allows the filter plate to play an important role in various industrial applications, especially when facing different process requirements, it can ensure the efficient operation of the filtration system.

The durability and low maintenance requirements of the filter plate are also one of its irreplaceable advantages in high-pressure filtration systems. High-quality filter plates are usually made of corrosion-resistant and wear-resistant materials, and can still maintain good filtration effects under long-term high-pressure working environments. This not only extends the service life of the filter plates, but also reduces the need for frequent filter plate replacement, thereby reducing maintenance costs and downtime, further improving overall production benefits.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt