Choosing the Right Filter Press for Your Manufacturing Process

2025.09.22

2025.09.22

Industry News

Industry News

- Basic Principles and Types of Filter Presses

Basic Principle:

A filter press is a device used to separate liquids and solids, widely used in industries such as wastewater treatment, chemicals, food, and pharmaceuticals. Its operating principle is to use a filter medium (such as filter cloth or filter plates) to pressurize a liquid containing solid particles into a filter chamber, thereby separating the liquid and solids.

Types:

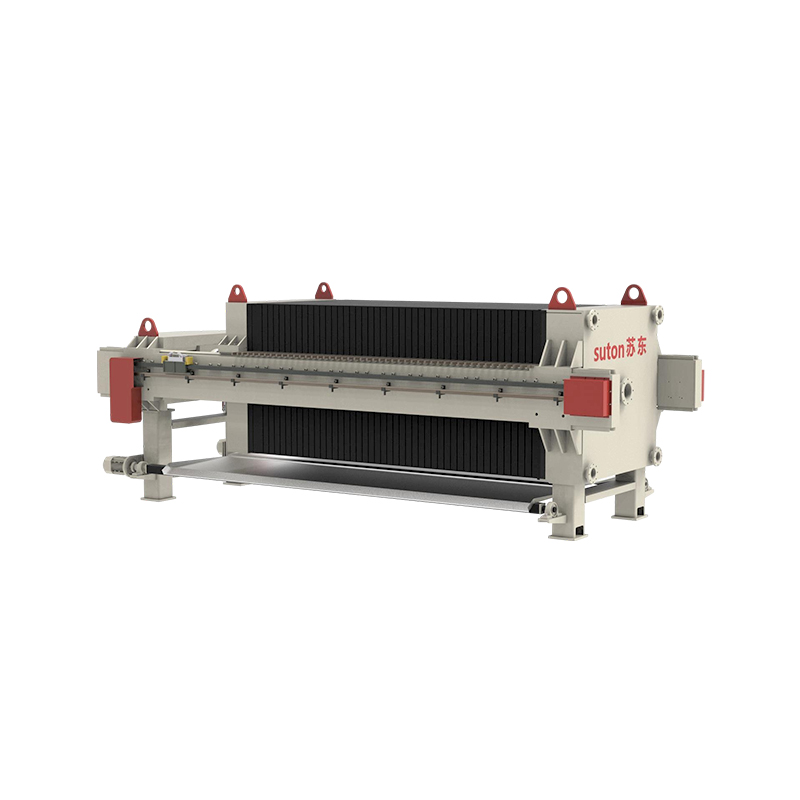

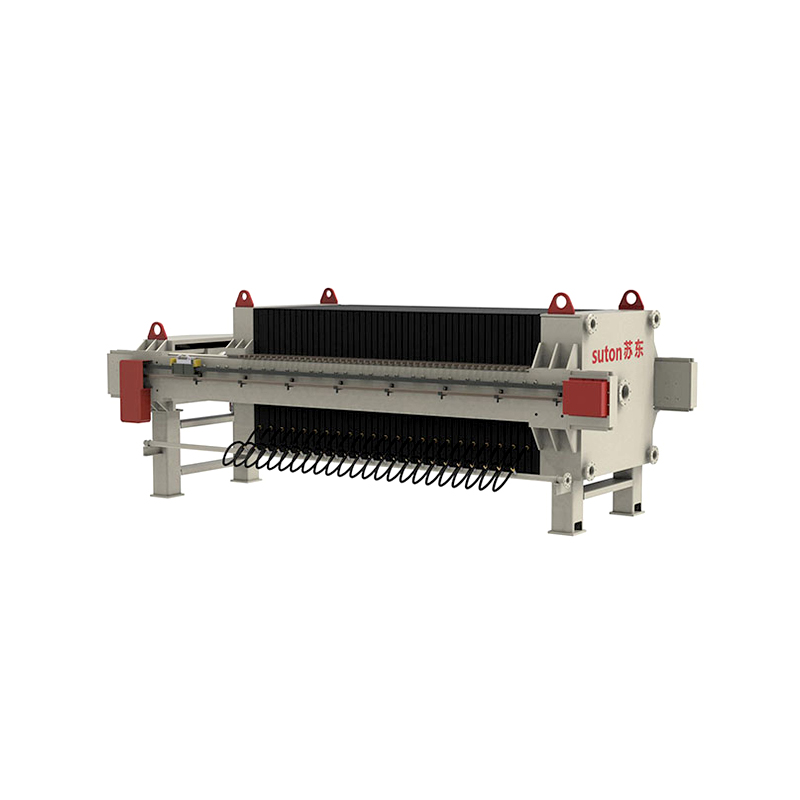

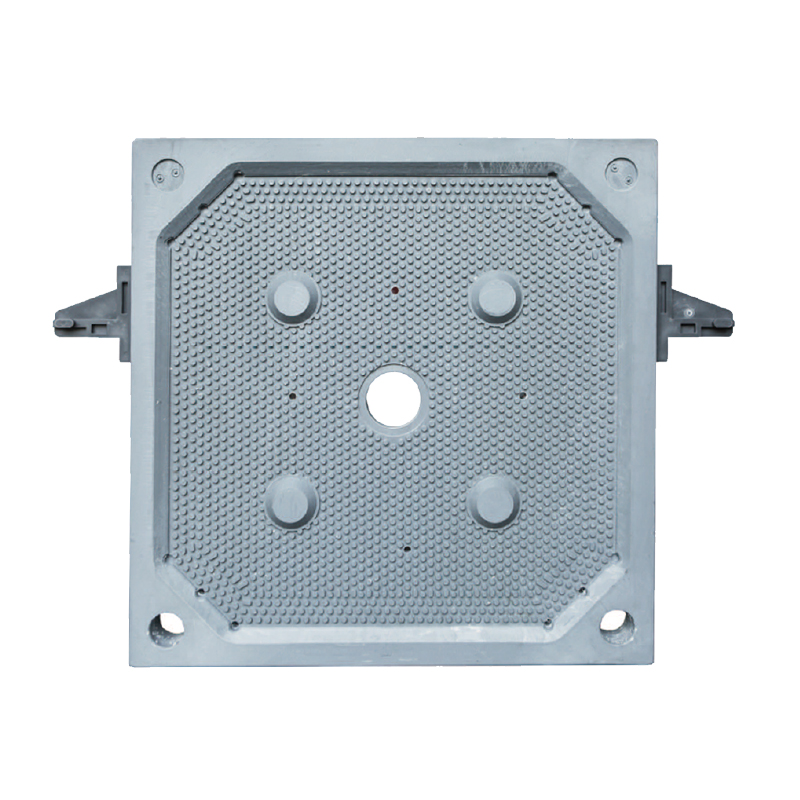

Plate and Frame Filter Press: The most common type, consisting of multiple filter plates and a filter frame. Filter cloth is placed between the filter plates. As the liquid passes through, solids are trapped on the filter cloth, while clean liquid flows out.

Frame Filter Press: This has a simpler structure. Filtrate enters through a filter plate frame, while solids remain within the frame.

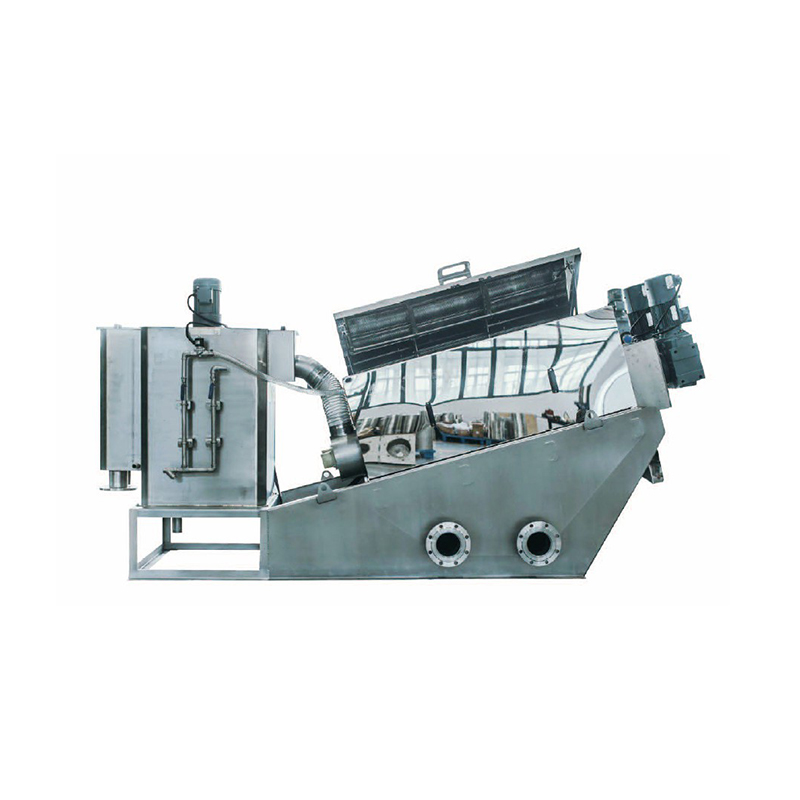

Belt Filter Press: Suitable for viscous materials, filtering is performed using a belt conveyor.

- Requirements Analysis in the Manufacturing Process

Key Points of Requirements Analysis:

Material Characteristics: Select the appropriate filter press based on the type of material to be filtered (e.g., liquid, slurry, suspension, etc.). For example, the chemical industry often handles highly corrosive chemical liquids, while the food industry handles more viscous juices and emulsions.

Flow Requirement: Determine the daily or hourly throughput to select adequate equipment. Flow directly impacts equipment size, filtration area, and operating pressure.

Filtration Fineness: Filter fineness or pore size directly impacts product quality. For delicate materials, higher-precision filter media may be required.

Degree of Automation: Automated equipment reduces manual intervention and improves production efficiency. Consider whether to choose a fully automatic or semi-automatic filter press to suit different production needs and budgets.

- Choosing Filtration Pressure and Filtration Area

Filtration Pressure:

Filtration pressure determines the degree of compression of the filter cloth and the effectiveness of solid material removal. Generally speaking, high pressure results in higher filtration efficiency, but it may also increase equipment wear and tear, leading to higher maintenance and operating costs. Low-pressure filtration is suitable for applications that do not require high filtration fineness.

Filtration Area:

When calculating the required filtration area, consider the throughput, filtration rate, and the characteristics of the solid material. A larger filtration area allows more liquid to be processed per unit time, making it crucial in large-scale production.

The filtration area is generally proportional to the size of the individual filter plates in the filter press. This can be increased by increasing the number of filter plates or using larger plates.

- Material Selection: Corrosion Resistance and High-Temperature Resistance

The Impact of Materials on Equipment Life and Performance:

Stainless Steel: Offers good corrosion resistance to most acidic and alkaline solutions and is suitable for most chemical and mining applications.

PVC/PP: Suitable for handling mildly corrosive materials at a lower cost, commonly used to treat certain liquids in the water treatment and food industries.

Rubber Coating: Protects equipment from corrosion and is particularly suitable for handling materials containing corrosive acids or chemical solutions.

High-Temperature-Resistant Materials: When handling high-temperature fluids (such as steam or hot liquids), special high-temperature-resistant materials such as titanium alloys or high-temperature-resistant plastics are required.

- Balancing Filtration Efficiency and Product Quality

Filtration Efficiency:

Processing Time: An efficient filter press should complete its filtration task in a short time, reducing production cycle time. Residue Content: An excellent filter press should effectively remove suspended matter, ensuring high purity of the filtered liquid and minimizing residue content.

Cleaning Effectiveness: Regular cleaning of the filter press is crucial for maintaining its long-term stability. Automated cleaning systems can reduce manual cleaning workload and ensure effective filtration.

Balancing Product Quality:

Excessive pursuit of efficiency can compromise filtration accuracy, while overemphasizing accuracy can lead to decreased production efficiency. Therefore, it is necessary to strike a balance between filtration speed and accuracy based on different production needs.

- Ease of Operation and Maintenance

Operational Ease:

Automation: A highly automated filter press can reduce the need for manual operation, including automatic pressurization, automatic residue discharge, and automatic cleaning. The equipment should be equipped with a user-friendly control system to minimize the possibility of human error.

User Interface: The equipment's control panel should be simple and intuitive, with a user-friendly interface, allowing operators to easily monitor the equipment status in real time.

Maintenance Ease:

Filter Cloth Replacement: The filter cloth is a core component of the filter press and requires regular replacement. A simple filter cloth replacement design can significantly improve maintenance efficiency. Cleaning and Maintenance: High-quality equipment should be designed for easy cleaning and maintenance, such as easily accessible filter chambers for easy removal of debris.

- Cost and Budget Considerations

Initial Investment and Operating Costs:

Initial investment primarily includes equipment purchase, installation, and commissioning costs. Initial investment varies significantly depending on the equipment type and degree of automation.

Long-Term Operating Costs: These include energy consumption (such as power consumption for the pressurization system), filter cloth replacement frequency, and maintenance and repair costs. Choosing an energy-efficient filter press can reduce long-term operating costs.

Cost-Effectiveness:

Choosing the most suitable filter press within your budget is crucial. Excessively inexpensive equipment may not guarantee quality, while overly expensive equipment may exceed production needs. Select cost-effective equipment based on process requirements and production volume.

- Case Studies

Industry Applications:

Chemical Industry: In chemical production, filter presses are used to separate wastewater and solid materials after chemical reactions. Corrosion-resistant filter presses can effectively handle liquids containing strong acids or bases.

Mining: Filter presses are often used to separate solids from ore slurries during ore refining. The mining industry processes large quantities of slurry, placing high demands on equipment efficiency and durability.

Food Industry: Used for filtering liquids such as juice, oil, and dairy products. The food industry places high demands on equipment cleanliness and material hygiene, making it particularly important to select filter presses made of FDA-certified materials.

- Future Development Trends

Technological Advances:

Intelligent Control: With the development of Industry 4.0, filter presses are increasingly adopting intelligent operation, including real-time monitoring and automatic adjustment of filtration parameters.

Energy-Saving Design: The new generation of filter presses focuses on reducing energy consumption and employing more efficient filtration and pressurization systems to improve overall efficiency.

Environmental Protection: Future filter press equipment will place greater emphasis on environmental protection, reducing energy consumption, optimizing waste disposal, and minimizing the environmental impact of production.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt