How to adjust the design parameters of filter press according to material characteristics

2025.09.29

2025.09.29

Industry News

Industry News

- Particle Size

Impact: Particle size directly determines the selection of filter cloth and filter plates. Large particles are more likely to clog the filter cloth than fine particles, affecting filtration speed and potentially causing interruptions. Particles that are too small can increase the solids content of the filter cake, reducing the filtrate flow rate and making efficient separation difficult.

Adjustment Suggestions:

For large particles, choose filter cloth and filter plates with larger pore sizes to avoid clogging.

For fine particles, use filter cloth with smaller pore sizes to improve filtration accuracy and reduce solids residue in the filtrate.

When designing, ensure the filter cloth has strong anti-clogging capabilities. This can include using multiple layers of filter cloth or selecting a surface treatment suitable for fine particles.

- Material Viscosity

Impact: Higher material viscosity reduces the fluidity of the liquid, resulting in slower filtration rates and increased clogging during filtration. Highly viscous materials also increase filtration pressure, causing damage to the filter cloth or excessive load on the filter plates.

Adjustment Suggestions:

For high-viscosity materials, it is recommended to increase filtration pressure to help push the material through the filter cloth. Choose filter cloths or filter plates specifically designed for filtering high-viscosity fluids. For example, increase the filter cloth's flow capacity and permeability to reduce filtration resistance.

Use a heating system to reduce material viscosity, such as heating the material before filtration, especially for water-based materials.

For extremely high-viscosity materials, auxiliary equipment such as a vibrating screen or a spray system may be necessary to reduce material buildup on the filter cloth.

- Solids Content

Influence: The solids content of the material determines the thickness of the filter cake and filtration efficiency. A high solids content means more solids must be separated, typically requiring longer filtration times or higher pressures to achieve better filtration results.

Adjustment Recommendations:

For high-solids materials, choose a larger filter press to ensure adequate space for the filter cake.

Increase the number of filter presses or design multiple filter plate layers to increase processing capacity.

In actual operation, you can optimize run time to increase filtration efficiency per cycle and reduce cycle time. For materials with extremely high solids content, pretreatment may be necessary to reduce the solids load, such as through centrifugation or sedimentation tanks.

- Chemical Composition

Influence: Different chemical compositions can cause corrosion and damage to filter cloths or filter plates during filtration, or affect the properties of the filter cake and filtrate. For example, acidic or alkaline materials can corrode metal components, causing equipment failure or shortening equipment life.

Adjustment Suggestions:

For corrosive materials, corrosion-resistant filter cloths and filter plates can be used, such as stainless steel, polypropylene (PP), or fluoroplastics.

For flammable, explosive, or toxic materials, the design should consider safety considerations for sealing and gas emissions to avoid harm to the environment and operators.

If the chemical properties of the material significantly affect the equipment, coated or specially treated filter cloths can be selected to ensure chemical resistance.

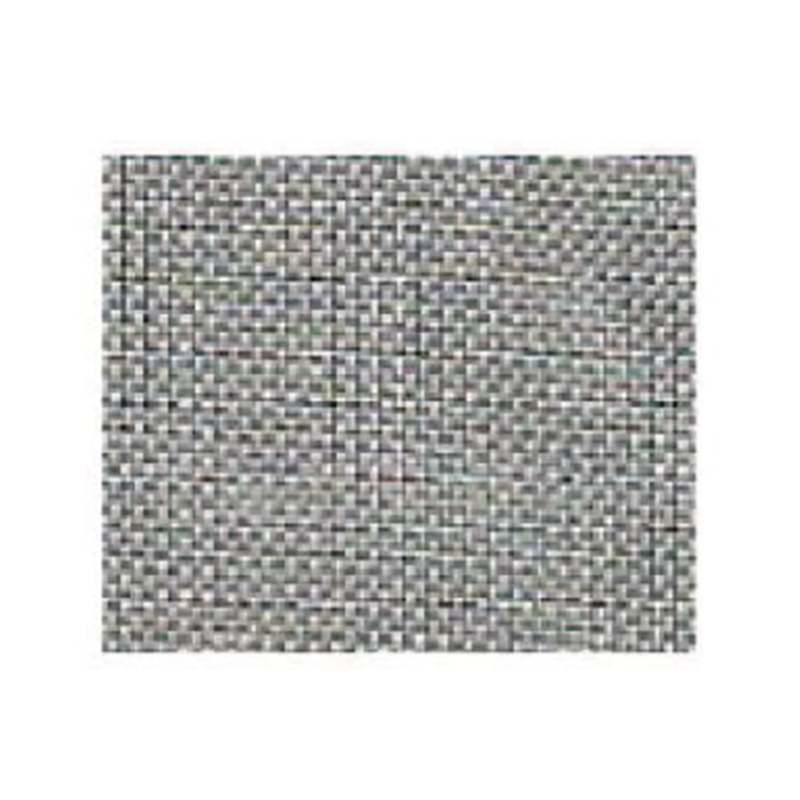

- Filter Media Selection

Influence: The material's particle distribution, chemical properties, and particle size determine the required filter media type. A filter cloth that is too coarse may not effectively capture fine particles, while a filter cloth that is too fine may clog and affect filtration efficiency. Adjustment Suggestions:

For materials with larger particles, use filter cloth with larger pores to prevent excessive particle accumulation on the filter cloth surface.

For materials with fine particles, choose filter cloth with smaller pores to prevent fine particles from entering the filtrate.

Based on the chemical properties of the material, select filter cloth with good chemical stability and wear resistance, such as polyester, polypropylene, or nylon.

For materials with particularly fine particles, use multiple layers of filter cloth or filter cloths made of different materials to improve filtration efficiency.

- Filter Press Pressure

Influence: Filter press pressure directly affects the dryness of the filter cake and the filtration rate. Appropriate pressure can improve filtration efficiency, but excessive pressure can damage the filter cloth or deform the filter plates, thereby shortening the service life of the equipment.

Adjustment Suggestions:

High pressure can be used for difficult-to-dewater materials, especially those with high viscosity or high solids content, to effectively improve filtration efficiency.

For materials that may damage the filter cloth during filtration, avoid excessive pressure and choose a moderate pressure to ensure safe operation of the equipment.

When processing materials of different properties, the operating pressure of the filter press can be adjusted according to the specific filtration performance.

- Temperature Effects

Impact: The viscosity, solids content, and flowability of materials may vary significantly at different temperatures. For example, some materials decrease in viscosity at higher temperatures, improving filtration performance. Conversely, some materials may crystallize or react at high temperatures, resulting in reduced filtration efficiency.

Adjustment Suggestions:

For materials with high viscosity at low temperatures, a heater can be used to increase the material temperature, thereby reducing viscosity and improving filtration efficiency.

For materials that may undergo chemical reactions at high temperatures, high-temperature-resistant materials, such as high-temperature filter cloth, should be selected to protect the equipment from damage.

During operation, pay attention to the impact of temperature on material properties and adjust the equipment's temperature control system as necessary.

- Filter Cake Dehydration

Impact: The dehydration properties of the filter cake directly determine the efficiency of the filtration process. If the filter cake cannot be dehydrated effectively, it may result in high moisture content, making subsequent processing more difficult and even affecting the quality of the filtrate.

Adjustment Suggestions:

For materials that are difficult to dehydrate, the dryness of the filter cake can be improved by increasing the filtration time or pressure. Select filter cloth materials with high dewatering capacity or optimize the filter cloth structure to improve filtration efficiency.

Optimize the filter press cycle to maximize dewatering of each filter cake layer and reduce residual moisture.

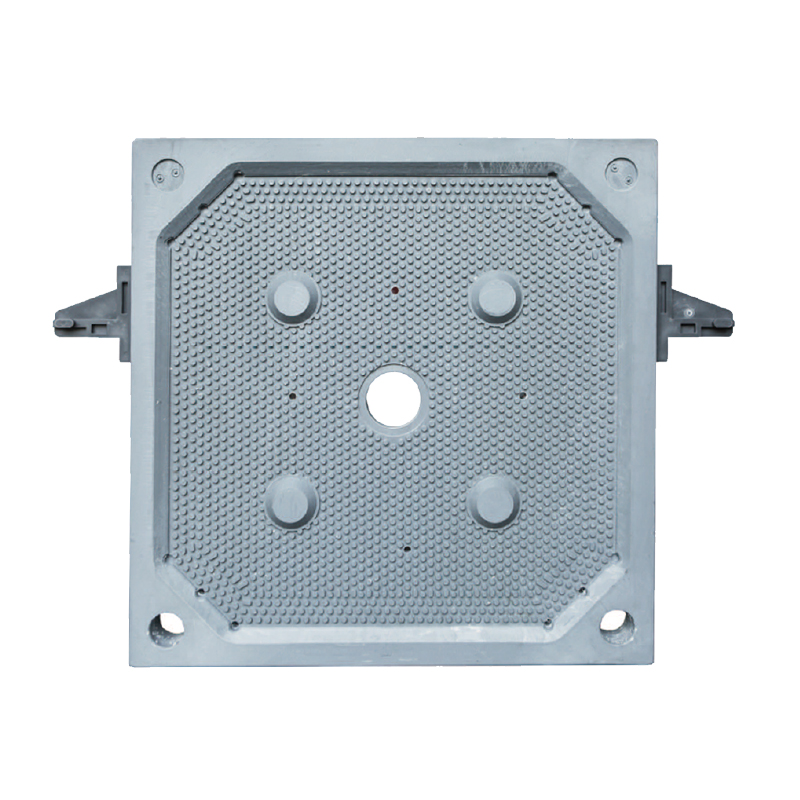

- Filter Plate Gap Design

Impact: The filter plate gap determines the filter cake thickness and filtration efficiency. Too small a gap may restrict fluid flow, resulting in reduced filtration efficiency; too large a gap may result in excessive filter cake thickness, affecting subsequent dewatering and separation processes.

Adjustment Suggestions:

For materials with larger particles, increase the filter plate gap to prevent clogging.

For viscous materials, consider reducing the filter plate gap and increasing the filter press pressure to promote better solid-liquid separation.

When designing the filter plate gap, balance the material characteristics to ensure flowability and filtration efficiency.

- Filtrate Treatment

Impact: The filtrate may contain hazardous substances or chemical components that require further treatment. Filtrates from different materials may require specialized treatment methods, such as precipitation, chemical reaction, or recovery. Adjustment Suggestions:

Depending on the nature of the filtrate, a specialized recovery system, such as a chemical reaction tank, concentration unit, or sedimentation tank, may be necessary to treat dissolved matter in the filtrate.

During the design process, consideration should be given to supporting filtrate treatment facilities to ensure environmental safety.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt