Filter Plate: A Comprehensive Guide to Understanding Its Role in Filtration Systems

2025.07.28

2025.07.28

Industry News

Industry News

Introduction:

In modern industry and environmental protection, the application of filtration systems is ubiquitous. As a key component of filtration equipment, filter plates directly affect the filtration efficiency and the operating stability of the system. From water treatment to petrochemicals to the food and beverage industry, filter plates play a vital role.

1. What is a filter plate?

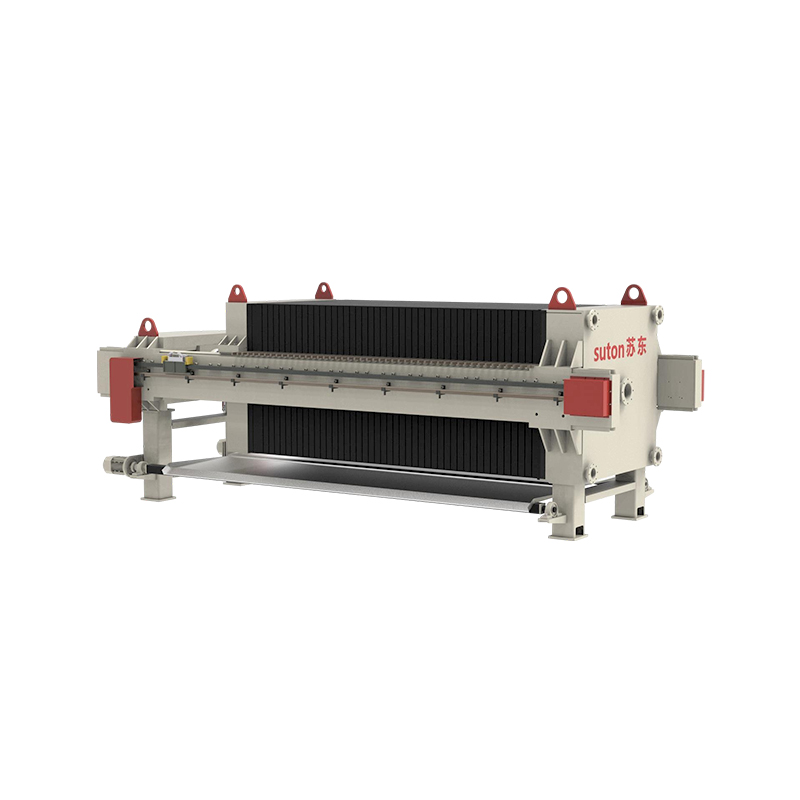

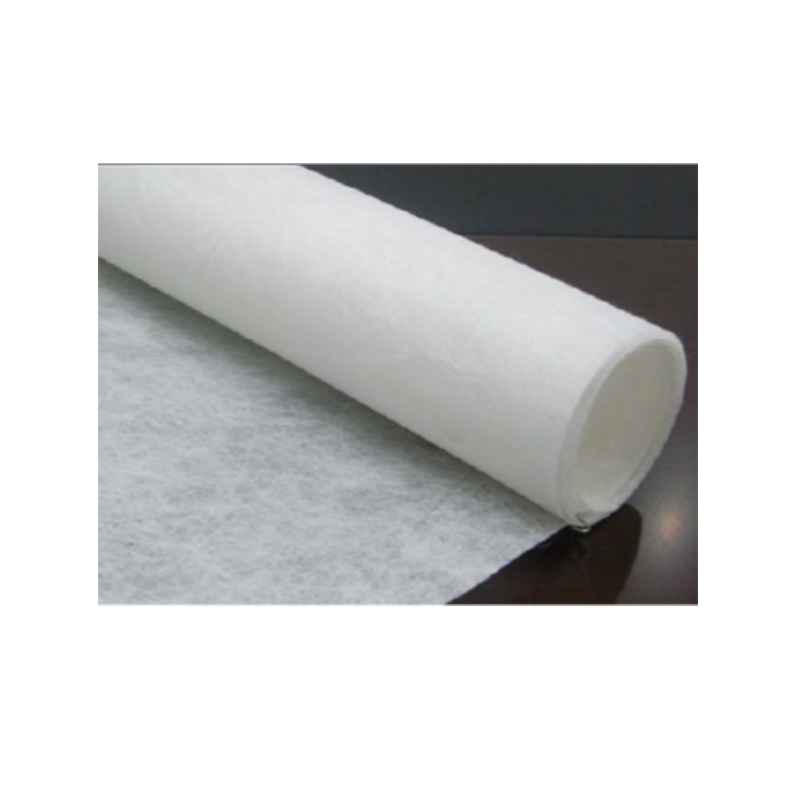

A filter plate is a plate-shaped device used in industrial filtration systems, usually made of a strong and corrosion-resistant material such as plastic or metal. Its main function is to support the filter medium (such as filter cloth or filter screen) and separate the fluid through its own pore structure. The design of the filter plate usually includes multiple filter holes or channels to accommodate the filter medium and can also withstand the pressure and flow rate in the system.

The core function of the filter plate is to provide a filtration area and effectively separate solid particles or impurities in the fluid through mechanisms such as physical, chemical or charge forces. It has a wide range of applications in many industries, especially in water treatment, chemical engineering, food industry and other fields.

2. How the filter plate works

The working principle of the filter plate is very simple and intuitive. Its basic operation method is to physically separate liquids or gases through the pores of the filter medium. When the liquid or gas enters the filtration system, it will pass through multiple channels of the filter plate. Filter cloth, filter screen or other media will be attached to the surface or pores of the filter plate, which can effectively intercept and remove solid particles in the fluid.

Particle interception: When the fluid with impurities enters the filter plate, the solid matter with larger particles will be trapped on the surface or filter cloth because it cannot pass through the pores.

Fluid separation: The fluid that passes through the filter medium continues to flow out and becomes a purified fluid.

The design of the filter plate usually adopts multiple superimposed filter layers, each with different pore sizes or different filtering capabilities to achieve a gradual filtering effect.

3. Main types of filter plates

Depending on the usage scenario and filtering requirements, there are many types of filter plates, each with its specific advantages and application areas.

Frame filter plate

The frame filter plate is a design for large-scale industrial filtration systems. This filter plate has a strong structure and can withstand high pressure. Usually, this type of filter plate is used in conjunction with a pressure filter and is widely used in water treatment, sludge dewatering and other scenarios.

Porous filter plate

This filter plate has a small pore size and is suitable for precision filtration requirements. They are often used to remove fine particles in liquids, such as filtration in the chemical and pharmaceutical fields.

Flat filter plates

Flat filter plates are often used in applications that require higher filtration accuracy. Their flat design ensures that the liquid flows evenly through the filter medium. They are commonly found in laboratory equipment or small industrial equipment.

Circular or disc filter plates

In some special filtration equipment, the filter plates may be designed in a circular shape to better suit specific filtration systems, especially for applications in continuous filtration processes.

4. Material selection for filter plates

The material of the filter plate directly affects its service life, filtration effect, and adaptability. Common materials include:

Plastics (such as polypropylene)

Polypropylene is one of the most common filter plate materials, with good corrosion resistance and light weight. It is suitable for low-temperature environments such as water treatment and food industry. Plastic filter plates have a lower cost, but are not suitable for extremely high temperatures and pressures.

Stainless steel

Stainless steel filter plates have extremely high strength and high temperature resistance, and are suitable for high temperature and high pressure environments such as chemical processing, petrochemical, and metallurgical industries. Stainless steel is also very corrosion-resistant and suitable for handling a variety of corrosive liquids.

Rubber and polyurethane

Rubber and polyurethane materials are often used for filter plates that require higher elasticity and wear resistance. They are commonly found in industries such as mining and sewage treatment, and can withstand a certain degree of physical impact.

Ceramics

Ceramic filter plates have extremely strong high temperature resistance and filtration accuracy, and are suitable for extreme environments of high temperature and high pressure, especially for fine particle filtration of liquids.

5. Application of filter plates in different fields

Filter plates are widely used in multiple industries, and each field has different requirements and functions for filter plates.

Water treatment

During the water treatment process, filter plates are often used to remove suspended matter, silt and impurities in water. By using filter plates with suitable pore sizes, pollutants in water sources can be effectively reduced and water quality can be improved.

Food and beverage industry

The food and beverage industry has very high requirements for product quality. Filter plates in this field are mainly used to filter raw materials, remove unnecessary particles and impurities, and ensure the purity and safety of products during the production process.

Chemical industry

In the chemical industry, filter plates are used to separate solid impurities in chemical solutions to help obtain pure chemical raw materials. The material of the filter plate usually needs to meet corrosion resistance and high temperature requirements.

Mining and metallurgy

In the mining and metallurgical industries, filter plates are often used to separate ore pulp and smelting liquid. They help remove unwanted impurities from ores, improving production efficiency and resource utilization.

6. How to choose the right filter plate?

When choosing the right filter plate, the following factors need to be considered comprehensively:

Type and particle size of filter media: Different applications require filter plates with different pore sizes and materials to ensure that particles can be effectively retained.

System pressure and temperature: The pressure and temperature resistance of the filter plate must meet the working requirements of the system to avoid damage under high pressure or high temperature.

Chemical compatibility: For liquids with special chemical properties, it is necessary to select materials with good corrosion resistance, such as stainless steel or polypropylene.

Ease of cleaning and maintenance: Some filter plates are designed to be easy to clean, which helps to reduce maintenance costs.

7. Maintenance and care of filter plates

In order to extend the service life of the filter plate and ensure the filtering effect, regular inspection and maintenance are essential.

Regular cleaning: The surface of the filter plate is prone to accumulate particles and impurities, so it needs to be cleaned regularly. Filter plates of different materials have different cleaning methods. Plastic filter plates can be cleaned with acid and alkali, while metal filter plates may require high-pressure water gun cleaning.

Check for damage: During use, the filter plate should be checked regularly for cracks, corrosion or wear, and replaced or repaired in time.

Pressure monitoring: Keep the pressure in the system within a safe range to avoid the filter plate from breaking due to excessive pressure.

8. Future filter plate technology trends

With the continuous advancement of technology, the design and application of filter plates are also constantly innovating.

Nanotechnology: Nanotechnology can be used to improve the filtration accuracy of filter plates and enhance their ability to filter tiny particles.

Intelligent monitoring system: Modern filtration systems have begun to use intelligent monitoring, using sensors to monitor data such as filtration efficiency, flow rate and pressure in real time, helping to detect problems and make adjustments in a timely manner.

Application of environmentally friendly materials: With the increase in environmental awareness, future filter plates may use more renewable or environmentally friendly materials to reduce the burden on the environment.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt