How to maximize the energy efficiency of your filter press: tips for optimizing operation and saving energy

2025.08.04

2025.08.04

Industry News

Industry News

1. Optimize feed conditions: Ensure efficient operation.

Even feed to avoid concentrated loads.

Filtrate feed must be uniform. Excessive load concentrated on a single filter plate can cause localized blockage or poor filtration performance. To avoid this, it is recommended to use an automated feed system. This precisely controls the flow rate, ensuring even distribution of liquid across the filter plates and reducing energy waste. Efficient feed control ensures more stable filtration performance, reducing unnecessary downtime and improving equipment efficiency.

Adjusting the appropriate feed pressure.

Setting the feed pressure is crucial to the energy efficiency of the filter press. Excessive pressure increases power consumption and can cause increased wear and tear on the equipment, shortening its lifespan. Therefore, feed pressure must be precisely adjusted based on material characteristics (such as viscosity and solids content) to avoid wasted power. Correctly setting the pressure not only increases filtration speed but also reduces damage to the equipment, extending its lifespan.

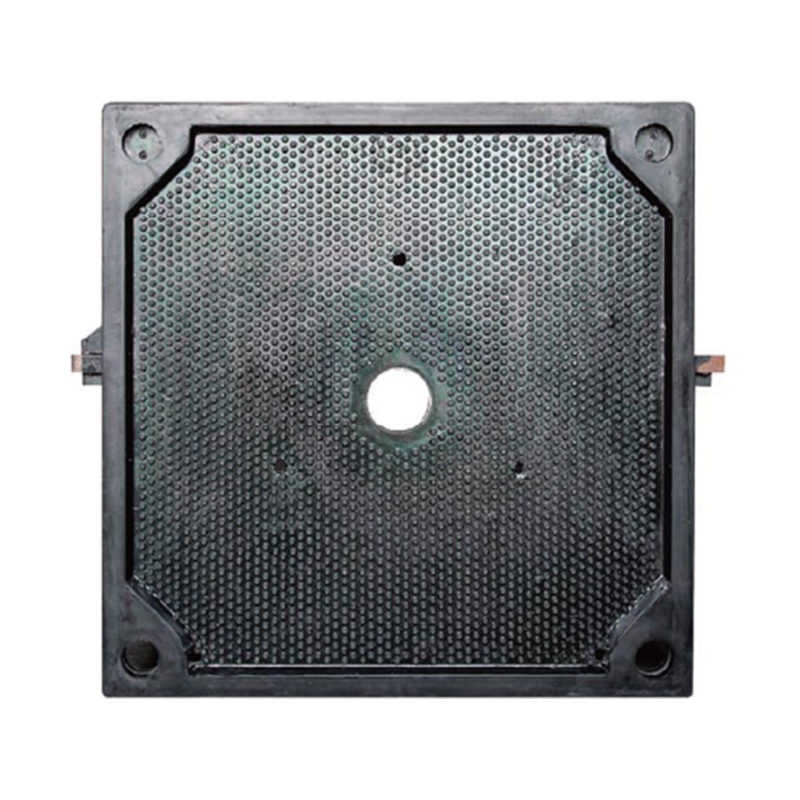

2. Selecting the appropriate filter cloth and filter plates: Improve filtration performance.

Selecting high-efficiency filter cloth reduces energy consumption.

The choice of filter cloth directly determines filtration performance. High-quality filter cloth offers improved permeability and lower resistance, accelerating filtration. Using high-quality filter cloth increases the flow rate of the filtrate, reduces operating time, and thus reduces energy consumption. Choosing the appropriate filter cloth type and pore size for each application and ensuring its high efficiency can maximize the energy efficiency of the filter press.

Clean the filter cloth regularly to prevent clogging. Impurities and solids accumulated on the filter cloth increase filtration resistance, reducing filtration efficiency. Prolonged cleaning of the filter cloth not only increases operating time but also energy consumption. Therefore, regularly cleaning the filter cloth to maintain its cleanliness can significantly improve filtration efficiency and reduce energy consumption. Regular maintenance also extends the life of the filter cloth, reducing long-term operating costs.

3. Optimizing the Filter Press Cycle: Reducing Unnecessary Time Waste

Rationally set the filtration cycle to avoid over-filtration. Excessively long filtration cycles not only waste energy but also increase the workload of the equipment, increasing system energy consumption. To improve the efficiency of the filter press, it is necessary to precisely control the duration of each filtration cycle and adjust the filtration cycle according to actual needs. The intelligent control system monitors the filtrate concentration in real time and adjusts the filtration cycle appropriately, avoiding prolonged overfiltration and repeated operations.

Automated Control Improves Operational Precision

The automated control system automatically adjusts operating parameters such as filtration time and filter pressure based on real-time liquid concentration and system pressure. This intelligent adjustment eliminates the uncertainty and errors associated with manual operation, ensuring that the filter press always operates at the most energy-efficient level and avoiding unnecessary energy waste.

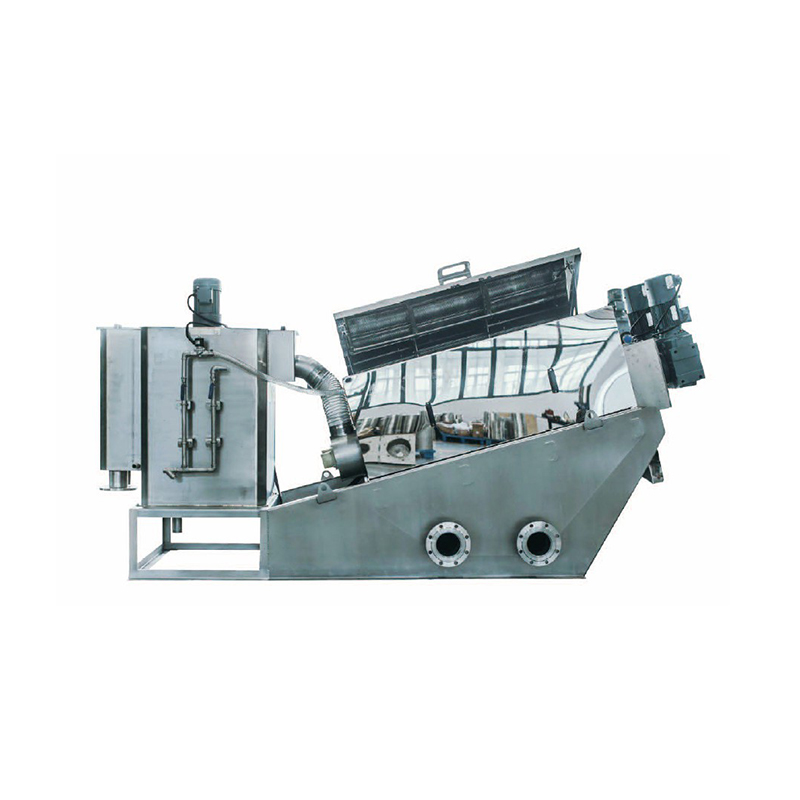

4. Improving Dehydration Efficiency: Optimizing Water Removal

Secondary Filter Press Technology

For certain high-solids sludge or wastewater, secondary filter press technology can further improve dehydration efficiency. While secondary filter press technology slightly increases energy consumption, its dehydration effect is highly significant, ultimately reducing wastewater discharge and solid waste disposal, and optimizing resource utilization. Secondary filter press technology not only helps increase the dryness of the filter cake but also effectively saves energy and costs in subsequent processing.

Hot Pressing Technology Improves Dehydration Efficiency

For some difficult-to-dehydrate materials, hot pressing technology can significantly improve dehydration efficiency. Heating the filter plates or the filtrate reduces the viscosity between solids and liquids, making separation easier. While this technology consumes additional heat energy in some cases, its energy savings are significant in large-scale applications.

5. Maintenance and Care: Ensure Efficient Equipment Operation

Regular Inspections Prevent Equipment Failures

Regularly inspecting the seals, filter plates, hydraulic system, and other components to ensure they are free of oil and water leaks, wear, and other defects can effectively improve filter press efficiency. Failures often require extended downtime and increased energy consumption to restore the equipment to operating condition. Regular inspection and maintenance can minimize failure rates and repair costs, ensuring long-term efficient operation.

Maintaining the Hydraulic System Prevents Energy Loss

The hydraulic system is a critical component of the filter press. Aging and contamination of the hydraulic fluid can reduce hydraulic efficiency, increasing energy consumption. Regularly changing the hydraulic fluid and keeping the system clean can maintain system efficiency and avoid unnecessary energy loss.

6. Energy-Efficient Drive System: Reduce Power Consumption

Variable Frequency Drive (VFD) systems optimize power usage.

Traditional motors typically operate at a fixed speed and cannot be flexibly adjusted to meet actual needs. Variable frequency drive (VFD) technology dynamically adjusts motor speed based on load changes, avoiding unnecessary power waste. VFDs automatically adjust motor power output based on real-time data, ensuring the equipment consumes minimal energy only when needed, significantly reducing power consumption.

High-efficiency motors reduce energy waste

Using high-efficiency motors not only improves overall equipment efficiency but also reduces power consumption. Choosing energy-efficient motors can significantly save energy costs and lower production costs over the long term.

7. Optimizing drainage systems: Improving energy efficiency

Reusing recycled water reduces water treatment costs

In many industries, the wastewater or liquid waste handled by filter presses contains a significant amount of recyclable water. By installing a recycling system, this water can be recycled and reused, reducing both wastewater treatment costs and the energy required for discharge. Utilizing recycled water not only helps reduce reliance on external water sources but also significantly reduces operating expenses.

Improving drainage efficiency and reducing time and energy consumption

Optimizing filter plate design to improve drainage efficiency can accelerate liquid discharge and reduce filtration time. This reduces energy waste, improves production efficiency, and optimizes equipment life and energy consumption.

8. Reduce Heat Loss: Maintain Stable Temperature

Insulation Measures Reduce Heat Loss

In cold environments, the filter press may lose heat due to low temperatures, affecting operating efficiency. Therefore, to reduce heat loss, the equipment can be insulated to maintain a stable internal temperature. Insulation not only improves equipment efficiency but also prevents equipment failure and excessive energy consumption caused by low temperatures.

Avoid Unnecessary Heating

In some operations, excessive heat consumption can occur, especially if the heating system is improperly configured. By precisely adjusting the heating temperature and ensuring that heating is activated only when necessary, unnecessary energy waste can be avoided, thereby improving the overall energy efficiency of the filter press.

9. Data Monitoring and Intelligent Analysis: Real-Time Operation Optimization

Real-time Monitoring System Ensures Optimal Operating Conditions

By installing sensors for temperature, pressure, flow, and other parameters, the filter press's operating status is monitored in real time. The system captures real-time data, enabling operators to adjust operating parameters promptly, ensuring the equipment is always operating at its optimal state and avoiding energy waste.

Intelligent Adjustment, Precise Control

An intelligent control system automatically adjusts operating parameters, such as filtration time and pressure, based on real-time monitoring data. Through intelligent regulation, the equipment can always maintain the most energy-efficient operating state, effectively avoiding unnecessary energy consumption.

10. Use High-Efficiency Auxiliary Equipment: Enhance Overall System Efficiency

Efficient Pumping Systems Reduce Energy Consumption

Using high-efficiency hydraulic pumps or feed pumps can reduce energy loss during liquid transfer. Compared to traditional pumps, energy-efficient pumps can significantly improve transfer efficiency and reduce electricity consumption.

Fan Optimization Reduces Energy Waste

For operations requiring air transfer, using high-efficiency fans can increase air flow and pressure while reducing unnecessary electricity consumption. Fan optimization helps ensure maximum energy efficiency for the entire system and improves the efficiency of the filter press.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt