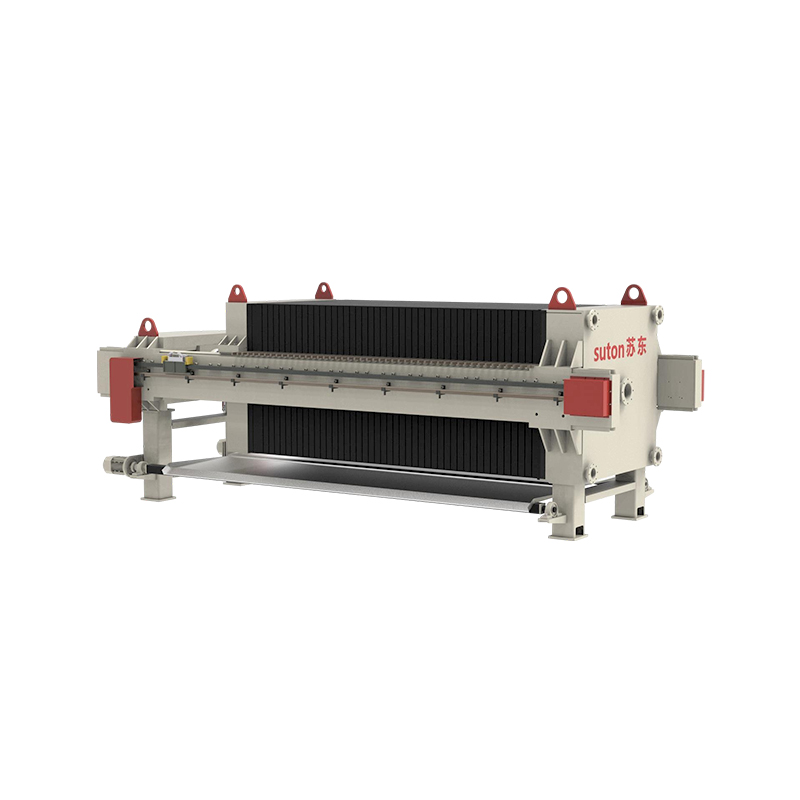

Filter Plate Cleaning and Maintenance Guide: Ensure Long-term and Efficient Equipment Operation

2025.08.18

2025.08.18

Industry News

Industry News

1. Regular Cleaning: Preventing Clogs and Performance Deterioration

Over extended use, filter plates can accumulate various impurities, such as grease, chemicals, and solid particles. These impurities not only affect the filter plate's filtration efficiency but can also cause equipment failure. Therefore, regular cleaning is essential to ensure efficient filter plate operation.

Cleaning Best Practices:

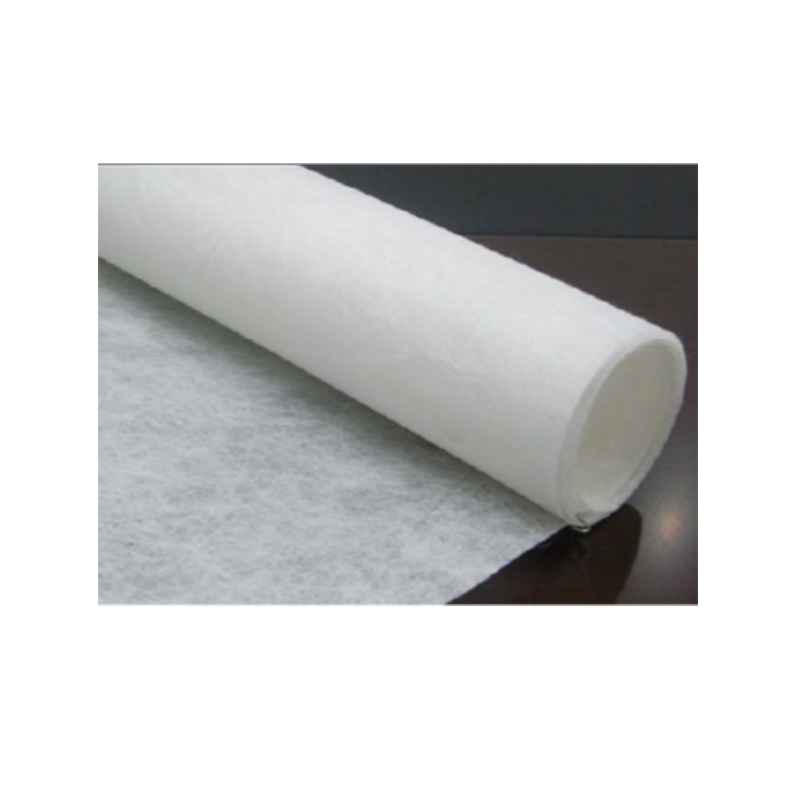

Preliminary Rinse: Use a high-pressure water jet to perform a preliminary rinse on the filter plate surface to remove large particles. This process not only removes accumulated material but also makes subsequent cleaning easier.

Chemical Cleaning: For filter plates heavily contaminated with oil, minerals, and scale, a specialized cleaning agent is necessary. Depending on the nature of the contaminant, choose an acidic, alkaline, or specialized cleaning agent. Chemical cleaning effectively breaks down deposits and restores the permeability of the filter plate's pores.

High-Temperature Cleaning: In some cases, warm water or steam cleaning can effectively remove difficult-to-remove dirt, especially oily substances. This cleaning method is suitable for filter plates operating in high-temperature environments.

Regular Deep Cleaning: Filter plates should be thoroughly deep cleaned periodically to remove accumulated dirt and deposits. This not only restores the filter plate's performance but also prevents long-term accumulation of dirt, which can lead to decreased filtration efficiency.

Recommended cleaning cycles:

Low-pollution environments: Clean every 3-6 months.

High-pollution environments: Clean monthly or more frequently to ensure the filter plates remain in optimal working condition.

2. Regular Inspections: Detect Problems Promptly and Avoid Equipment Downtime

Regularly inspecting the condition of the filter plates is key to preventing equipment failure and improving efficiency. Regular inspections can detect problems such as wear, cracks, and corrosion, thus preventing equipment downtime and production disruptions.

Recommended Inspection Items:

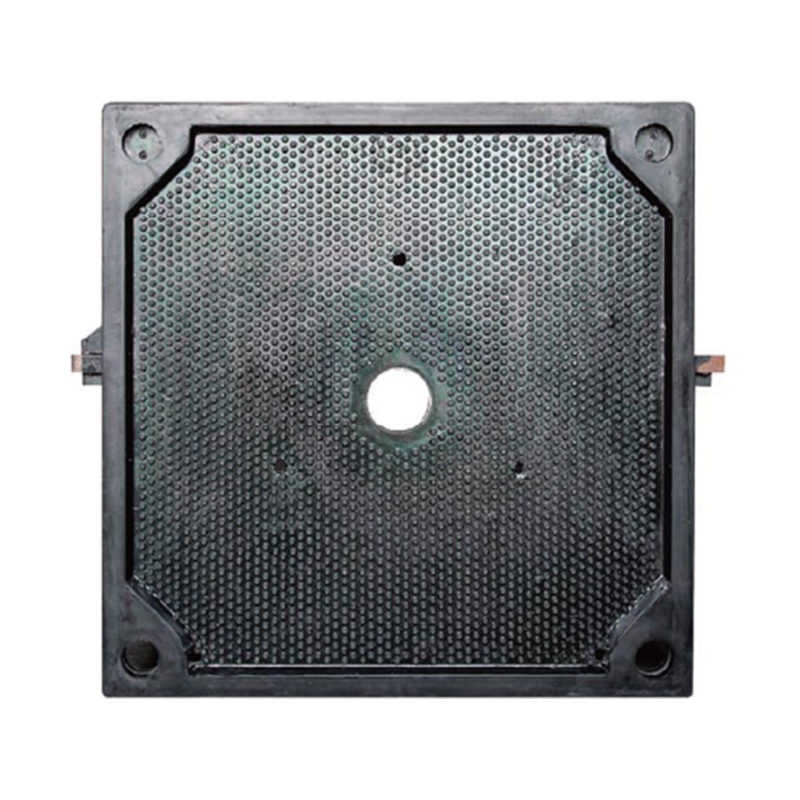

Surface Inspection: Inspect the filter plate surface for cracks, scratches, or corrosion. Large cracks in the filter plate may cause filtrate leakage, affecting filtration performance. Therefore, the integrity of the filter plate should be regularly inspected and damaged plates should be replaced promptly.

Pore Inspection: Use specialized equipment to check the permeability of the filter plate pores to ensure they are not clogged by contaminants. If clogged pores are detected, high-pressure water jets can be used to clean them.

Seal Inspection: The filter plate seal directly affects filtration performance and liquid leakage. Regularly inspect the seals for signs of wear and tear. If damaged or deteriorated, replace them promptly to maintain the stability of the filtration process.

Frame Inspection: Inspect the filter plate support frame for deformation, corrosion, or looseness. These issues can affect the stability of the entire system. Promptly repairing or replacing damaged frames can prevent further malfunctions.

3. Filter Plate Storage and Protection: Preventing Damage and Contamination

Proper storage and protection methods are crucial to extending the lifespan of filter plates. If filter plates are not properly stored, they may fail prematurely due to environmental factors or physical damage.

Key Storage Points:

Dryness and Ventilation: Filter plates should be stored in a dry, well-ventilated area, avoiding humidity to effectively prevent deformation, corrosion, and mold.

Avoid Overstacking: If filter plates must be stacked, avoid stacking them too high, as this may cause deformation or damage to the lower filter plates. It is best to store the filter plates flat, with adequate space between each layer.

Prevent Chemical Contamination: Avoid contact between filter plates and corrosive or toxic chemicals. Prolonged exposure to these conditions may damage their structure and function.

4. Timely Replacement of Worn Parts: Ensuring Long-Term Stable Operation

The service life of a filter plate depends not only on its quality but also on the maintenance of its components. Components such as seals and support frames will wear or age after prolonged use and must be replaced promptly to ensure plate stability and filtration efficiency.

Replacement Timing:

Aging of seals: Aging seals can cause liquid leakage during filtration, affecting filtration performance. Sealing strips that become hard, cracked, or lose their elasticity should be replaced promptly.

Frame Damage: Corrosion or deformation of the support frame can prevent the filter plates from maintaining close contact, affecting filtration pressure and efficiency. Regularly inspect the support frame and replace damaged parts promptly.

Filter Plate Surface Wear: If the filter plate surface is severely worn and cleaning cannot restore its performance, it may need to be replaced. Increased differential pressure or leakage during filtration indicate filter plate damage.

5. Optimizing Operating Parameters: Improving Filtration Efficiency

Optimizing equipment operating parameters not only helps improve filtration efficiency but also reduces filter plate wear and maintenance frequency. Ensuring that operation complies with filter plate design requirements can effectively reduce the risk of equipment failure. Key Operating Parameters:

Pressure Control: The filter plates are subject to a certain amount of pressure during the filtration process. Excessive pressure may cause deformation and shorten their service life. It is recommended to strictly control the operating pressure according to the load-bearing capacity of the filter plates.

Flow Control: The flow rate of the filtrate should match the workload of the equipment. Excessive flow rates may cause the filter plates to clog, while excessively low flow rates may not guarantee efficient filtration. Therefore, the appropriate flow rate should be adjusted according to the properties of the filter material.

Temperature Control: Some filter plate materials are very sensitive to temperature, and high-temperature operation may cause their performance to deteriorate. It is recommended to monitor the temperature during the filtration process to avoid damage to the filter plates caused by excessive temperatures.

6. Selecting High-Quality Filter Plates: A Fundamental Solution

High-quality filter plates are essential for ensuring long-term, efficient operation of the equipment. Choosing durable, corrosion-resistant, and easy-to-clean filter plates can reduce maintenance frequency and improve filtration efficiency.

Criteria for Selecting High-Quality Filter Plates:

Corrosion Resistance: For filter plates used in chemical or high-temperature environments, materials with excellent corrosion resistance, such as polypropylene and polyethylene, must be selected to effectively resist attack by acids, alkalis, and other chemicals. Abrasion Resistance: High-quality filter plates are highly resistant to abrasion and can withstand prolonged use without deformation, shedding, or cracking.

Filtration Efficiency: The pore design of the filter plates should meet specific process requirements to ensure that the filtration efficiency of the material is not affected. Selecting the appropriate pore size and porosity can optimize filtration efficiency and reduce clogging.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt