Improved filtration efficiency, reduced operating costs: Advantages of the Sludge Filter Press

2025.08.11

2025.08.11

Industry News

Industry News

1. High Dewatering Capacity: Saves Treatment Costs and Improves Efficiency

One of the greatest advantages of the Sludge Filter Press is its superior dewatering capacity. The device uses high pressure to extract water from sludge, typically reducing the moisture content to below 20%. Compared to traditional sludge treatment technologies (such as centrifuges or belt filter presses), the Sludge Filter Press more effectively reduces sludge volume, making subsequent wastewater treatment operations more efficient. The sludge is compressed through filter pressing, reducing storage, transportation, and disposal costs, thereby lowering overall wastewater treatment operating costs.

Application Example: Many food processing companies have adopted the Sludge Filter Press for wastewater treatment, significantly reducing their energy consumption and operating expenses.

2. Energy and Operating Cost Savings: Environmentally friendly and efficient, reducing overhead expenses

Compared to other energy-intensive wastewater treatment equipment, the Sludge Filter Press consumes relatively low energy. Its operating principle is based on physical filtration, requiring no significant electricity to operate. Most Sludge Filter Presses are equipped with automated control systems that precisely control pressure and time during the filtration process, thus avoiding excessive resource consumption. Automated operation also effectively reduces equipment failure rates and the need for manual intervention, further reducing operating costs.

Energy Savings: For example, a chemical company reduced its annual electricity consumption by over 30% after replacing traditional centrifugal dewatering equipment with a Sludge Filter Press.

3. High-Quality Filtration: Ensures Compliance with Environmental Standards and Optimizes Discharge

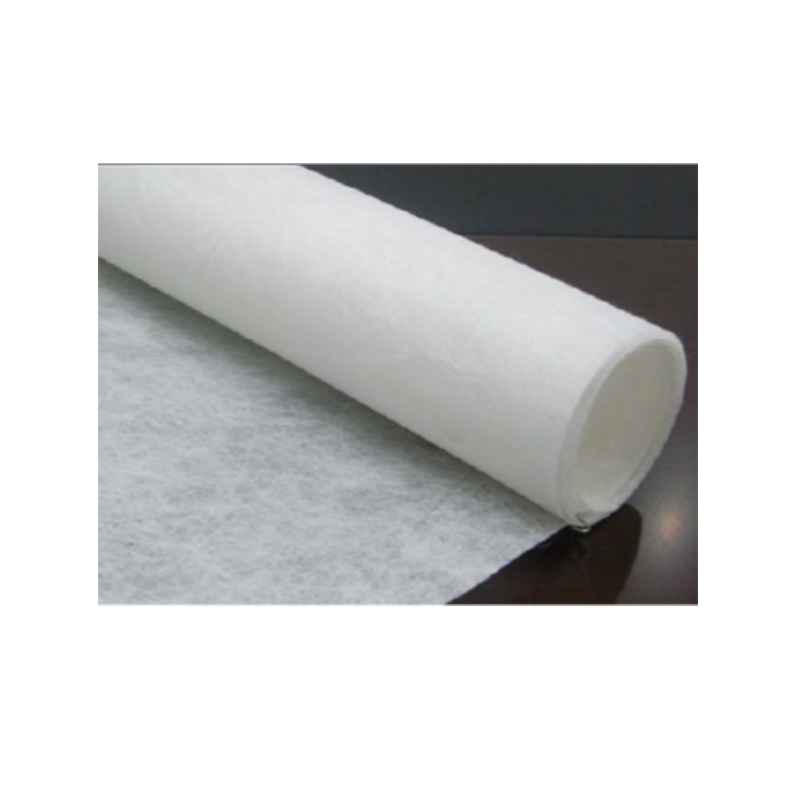

The Sludge Filter Press achieves precise filtration, effectively removing suspended solids and harmful substances from wastewater. The filter mesh and high pressure trap solids in the sludge, ensuring optimal moisture content after dewatering. This filtration performance not only helps improve wastewater discharge standards and comply with environmental regulations, but also significantly reduces environmental pressures on the company, avoiding fines and rectification issues associated with non-compliant discharges.

Case Study: A pharmaceutical company effectively removed harmful substances from its wastewater after using the Sludge Filter Press, successfully meeting environmental standards and avoiding significant environmental fines.

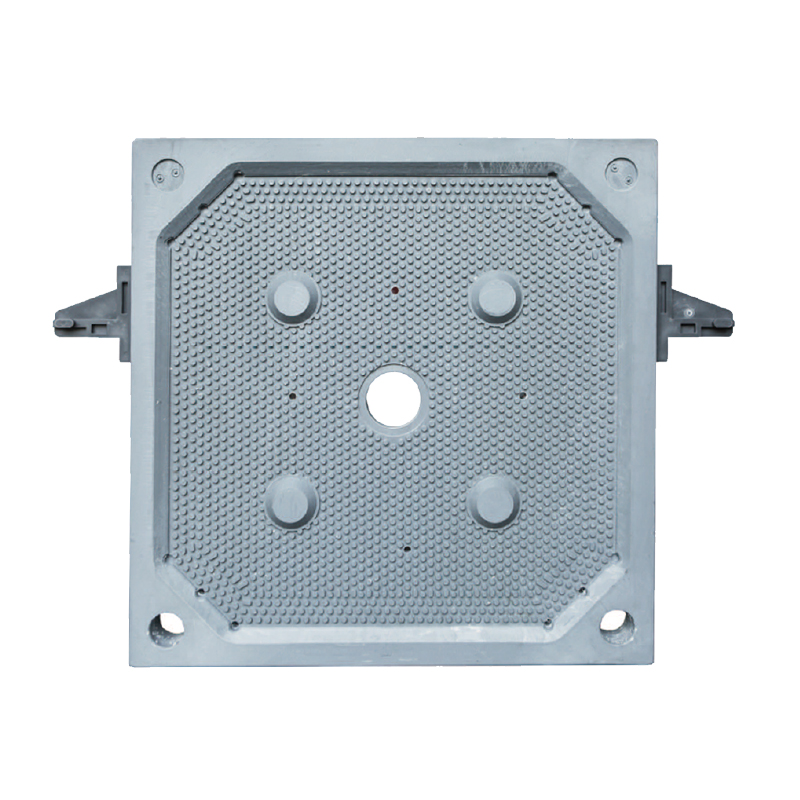

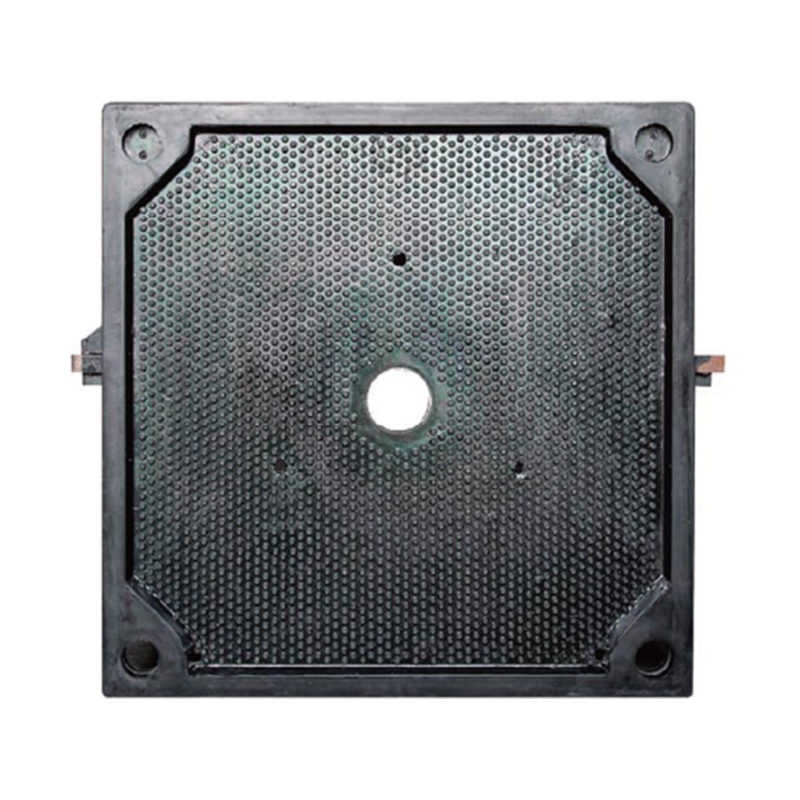

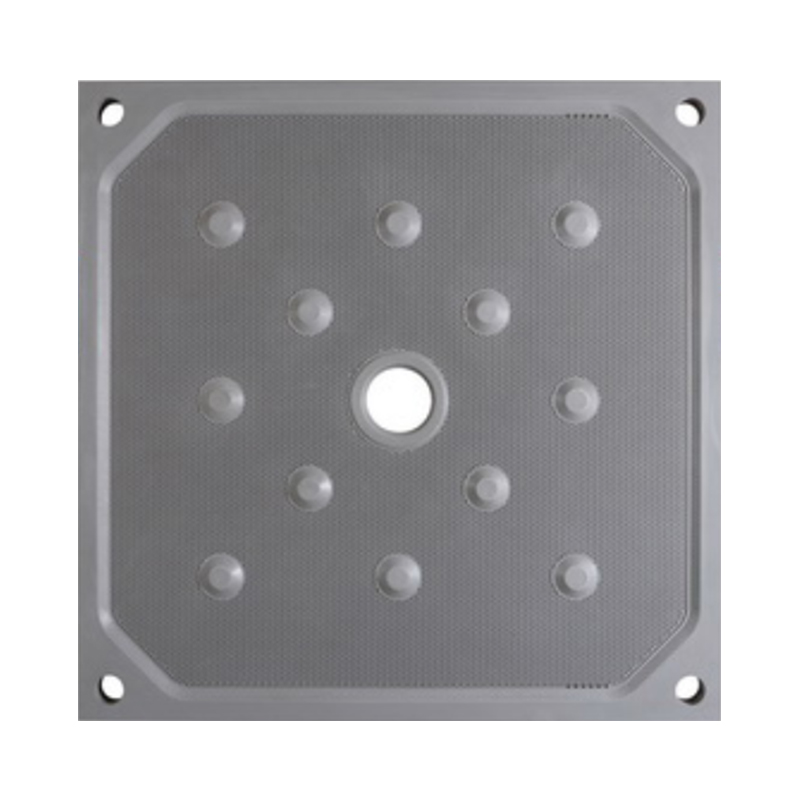

4. Easy Maintenance and Long Life: Reduces Equipment Replacement Frequency and Maintenance Costs

The Sludge Filter Press utilizes highly wear-resistant filter cloth and pressure plates, ensuring excellent performance even under high workloads. The filter cloth and pressure plates maintain high efficiency over time, requiring extended maintenance cycles and significantly reducing equipment replacement frequency. Consequently, companies no longer need to frequently inspect and replace parts, saving them money in the long term.

Customer Experience: A mining company stated that after using the Sludge Filter Press, their equipment has operated stably and maintenance costs have been significantly reduced, saving hundreds of thousands of yuan in maintenance costs.

5. Adaptability and Wide Application: Meeting Diverse Industrial Needs

The Sludge Filter Press's flexible design allows it to treat a wide range of sludge types, including chemical sludge, oil sludge, mining wastewater, food industry wastewater, and other industrial wastewaters. Whether it's high-viscosity wastewater containing grease or wastewater containing chemical reaction byproducts, the Sludge Filter Press efficiently handles it, ensuring stable wastewater treatment results in diverse production environments. This adaptability makes the Sludge Filter Press an ideal choice for a wide range of applications across various industries.

Industry Applications: For example, in the papermaking industry, food processing plants, and mineral processing plants, the Sludge Filter Press effectively handles complex wastewater compositions and meets environmental requirements.

6. Reduced Environmental Impact: Contributes to Business Sustainability

With increasingly stringent environmental regulations, businesses need to take measures to reduce their environmental impact. The Sludge Filter Press's efficient dewatering reduces the need for sludge transportation and handling, significantly reducing the environmental impact of transportation. Reducing sludge volume not only lowers treatment costs but also effectively reduces landfill pressure, reduces resource waste, and contributes to the company's sustainability goals.

Environmental Benefits: By using the Sludge Filter Press, companies can effectively reduce CO2 emissions from wastewater treatment and enhance their environmental image.

7. Automated Control System Improves Efficiency: Reduces human error and optimizes management

Modern Sludge Filter Press equipment is equipped with a highly automated control system. This system monitors the equipment's operating status, sludge dewatering progress, and filter cloth cleanliness in real time, automatically adjusting filtration pressure and cycle times as needed. This automated system not only improves treatment efficiency but also reduces manual intervention, lowering the risk of operational errors and equipment failure, thereby enhancing the stability and reliability of the entire wastewater treatment process.

Case Study: After installing a Sludge Filter Press with an automated control system, a steel plant not only improved treatment efficiency but also reduced operational complexity and maintenance time.

8. Economical and Significant Return on Investment: Long-Term Cost Savings

While the initial investment in the Sludge Filter Press may be higher than traditional equipment, its advantages in high efficiency and low maintenance costs enable companies to achieve significant operating cost savings over the long term. More efficient sludge dewatering saves companies significant transportation, landfill, and sludge disposal costs, resulting in a higher return on investment. For long-term operations, the Sludge Filter Press investment is undoubtedly worthwhile.

Economic Benefits: For example, a fertilizer company saved over 500,000 RMB annually by switching to a Sludge Filter Press, with a payback period of less than two years.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt