Filter Press Plates: The Key to Efficient Solid-Liquid Separation

2025.09.09

2025.09.09

Industry News

Industry News

- Introduction: What is a Filter Press?

Filter plates are a key component of a filter press, a device widely used in various industries for solid-liquid separation. They separate liquids from solids by applying pressure and are commonly used in industries such as wastewater treatment, mining, chemicals, and food processing.

The working principle of a filter press is that a series of filter plates and filter cloth form a filter chamber. Under pressure, the liquid is forced through the filter cloth, thereby separating solid particles. Filter presses are commonly used for highly concentrated solid-liquid mixtures such as slurries, wastewater, and chemical solutions.

- The Role of Filter Press Plates

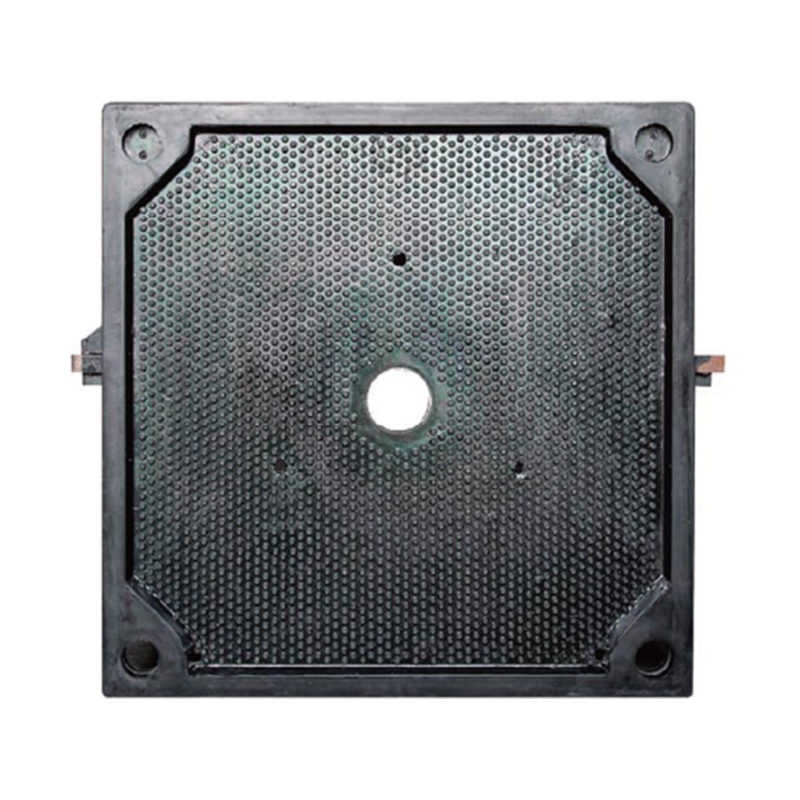

The primary function of filter plates is to support the filter cloth and separate the liquid from the solids by forming a filter chamber. Each filter plate typically has multiple pores on its surface, through which liquid can flow, while solids are trapped by the filter cloth, forming a filter cake.

The design of the filter plates helps provide high filtration efficiency when liquid passes through them. They are pressed together to form a seal, ensuring no liquid leaks and maximizing filtration effectiveness. Proper selection of filter plate material and design is key to improving solid-liquid separation efficiency.

- Types of Filter Press Plates

There are several common filter plate materials and types. Choosing the right plate type for each industry is crucial:

Polypropylene Plates: These materials are widely used due to their corrosion resistance, chemical resistance, and lightweight properties, making them suitable for most liquid processing applications. They are also well-suited for processing liquids with high or low pH values.

Stainless Steel Plates: Stainless steel offers enhanced heat and pressure resistance and is suitable for industries requiring high-intensity filtration, such as the chemical, petroleum, and food industries. These plates are typically used under more demanding operating conditions.

Ceramic Plates: Ceramic plates are ideal for high-precision solid-liquid separation, especially when filtering fine particles. They offer excellent mechanical strength and temperature resistance, but are relatively expensive.

- Importance of Plate Material in Performance

The choice of material directly impacts the plate's service life, filtration accuracy, and equipment maintenance costs. Different operating environments require different filter plate materials. For example, when handling strong acids or bases, polypropylene and stainless steel are common choices. However, for high-temperature or high-pressure environments, a more heat-resistant material may be required.

Polypropylene filter plates are often used for general solid-liquid separation tasks such as wastewater treatment due to their lightweight and corrosion resistance. Stainless steel filter plates are suitable for more demanding environments, especially in industries where chemical reactions require high resistance to the filter material.

- Solid-Liquid Separation Process: How Filter Press Plates Work

The core of the solid-liquid separation process is the high pressure between the filter plate and the filter cloth, which forces solid particles to form a filter cake within the filter cloth while the liquid flows out through the filter plate pores. This process is typically accomplished through mechanical pressure, typically hydraulic, pneumatic, or mechanical compression.

In a filter press, a liquid (usually a suspension containing particulate matter) passes through a series of filter plates and filter cloths into the filter chamber. As the liquid is pushed, solid particles are trapped on the filter cloth, forming a filter cake, while the clear liquid flows out through the filter plate pores and is collected. This process typically occurs over several filtration cycles.

- Applications of Filter Press Plates

Filter plates have a wide range of applications, covering a wide range of industries:

Environmental Protection: Filter plates play a vital role in wastewater treatment and sludge dewatering. Through efficient filtration, pollutants are removed from wastewater, and sludge is dewatered for subsequent processing.

Chemical Industry: They are used for chemical separation and purification. For example, in catalyst recovery, cleaning, or chemical solution filtration, filter plates effectively remove solid impurities.

Food Industry: In liquid filtration processes such as oil extraction, juice, and wine, filter plates effectively remove impurities, maintaining product purity and quality.

- Optimizing Filter Press Plate Efficiency

Selecting the Appropriate Filter Plate: Different liquid and solid types require filter plates with different pore sizes, materials, and designs. For example, larger particles are suitable for filter plates with larger pore sizes, while fine filtration requires a higher-density filter cloth and a smaller pore size filter plate.

Regular Maintenance and Cleaning: Cleaning and maintaining filter plates are crucial to maintaining their filtration performance. Regularly inspect filter plates for damage, scaling, and blockage. Cleaning them promptly can effectively improve filtration efficiency and extend equipment life.

- Troubleshooting Common Problems with Filter Press Plates

Common Problems and Solutions:

Filter Plate Blockage: After extended use, the filter plate pores may become clogged with solid particles, reducing filtration efficiency. Regular cleaning and backwashing can effectively address this issue.

Filter Plate Leakage: If the filter plate or filter cloth is not properly sealed, liquid leakage may occur, affecting efficiency. Check the sealing gasket, seal design, and filter plate compression, and adjust or replace the sealing material promptly.

Insufficient Cake Dehydration: Insufficient filter plate pressure or damage may result in incomplete cake dehydration. Check the compression system to ensure that the filtration pressure meets process requirements.

- Innovative Developments in Filter Press Plate Technology

Intelligent Monitoring: In recent years, many filter presses and filter plate systems have incorporated automated and intelligent monitoring technologies, such as remote monitoring and automated control systems. These technologies can monitor pressure, flow rate, and temperature during the filtration process in real time, automatically adjusting equipment operation and improving overall efficiency. Material Innovation: With technological advancements, new materials and coating technologies have been introduced into filter plate design. These new materials are more corrosion-resistant, heat-resistant, and can improve the filter plate's compressive strength.

Modular Design: Modern filter plates utilize a modular design that allows for flexible configuration based on actual needs, facilitating replacement of damaged filter plates while reducing overall equipment costs.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt