Optimizing Filtration Results: Common Techniques for Chamber Filter Press Operation

2025.09.01

2025.09.01

Industry News

Industry News

Introduction

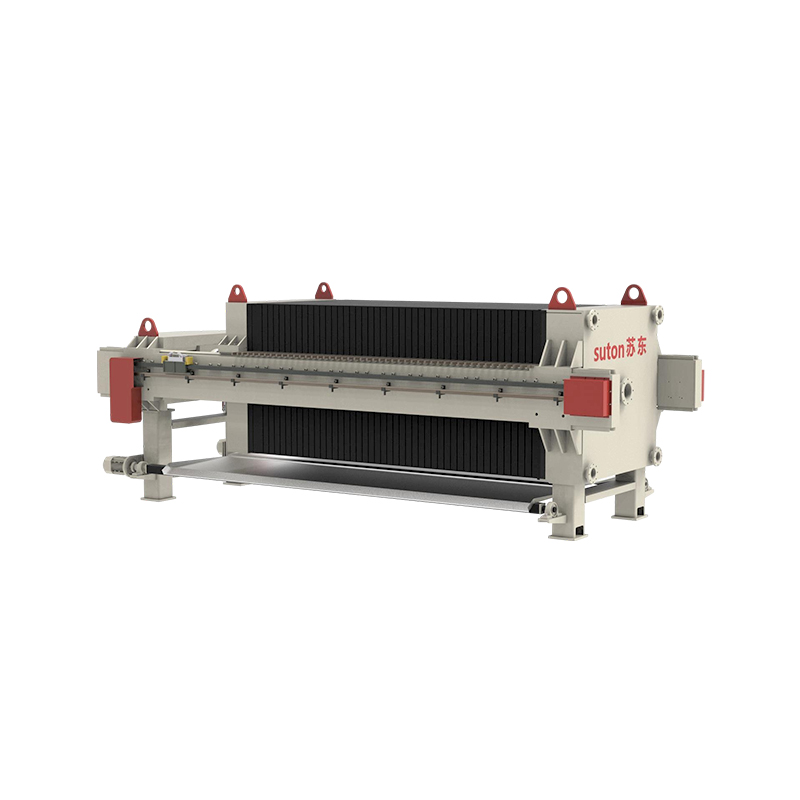

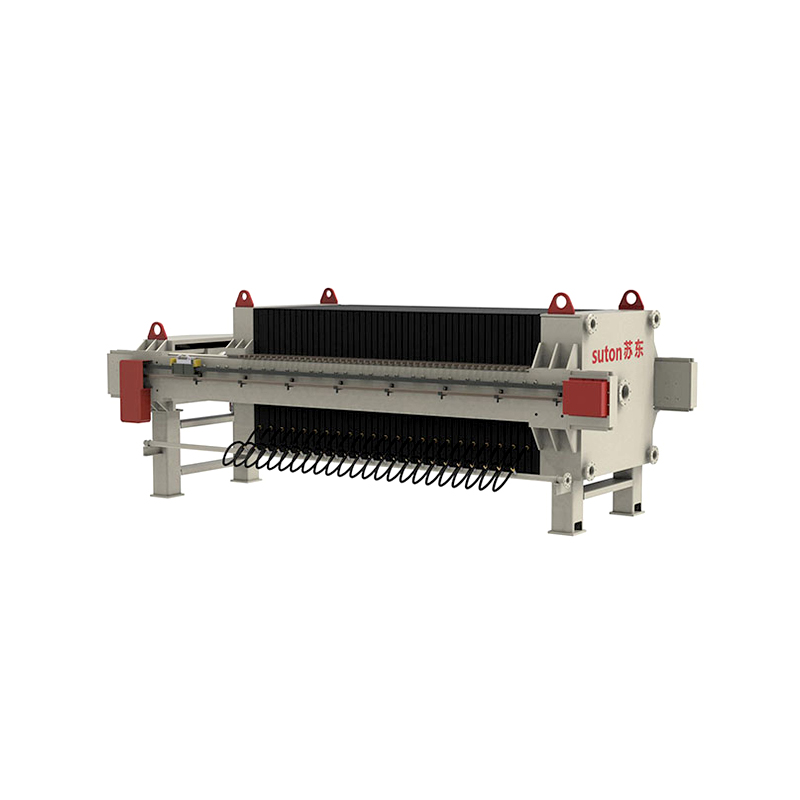

A chamber filter press is a device commonly used for solid-liquid separation and is widely used in industries such as mining, chemical processing, food and beverage processing, and wastewater treatment. Its primary operating principle is to separate liquids from solids in a material through mechanical pressure, achieving dehydration or filtration. Optimizing the filtration performance of a chamber filter press not only improves production efficiency, but also effectively reduces operating costs and enhances filtration accuracy.

1. Selecting the Right Filter Cloth

The Impact of Filter Cloth Material

The material of the filter cloth directly affects filtration performance and efficiency. When selecting a filter cloth, it is important to match it to the material's properties (such as particle size, chemical composition, and viscosity). Common filter cloth materials include polyester, polypropylene, and nylon. Improper selection can lead to clogging or perforation, thus compromising filtration performance. For materials with fine particles, a filter cloth with a higher fiber density can effectively improve filtration accuracy. For materials containing corrosive substances, a filter cloth with high corrosion resistance is required.

Filter Cloth Cleaning and Replacement Cycle

Filter cloths can easily become clogged during use due to material deposits or the accumulation of solid particles, reducing filtration efficiency. Therefore, regular cleaning of the filter cloth is essential. Avoid using overly strong chemical cleaning agents during cleaning to avoid damaging the filter cloth's fiber structure. The filter cloth has a limited service life. If it shows visible wear, tear, or blockage, it should be replaced promptly to ensure continued efficient operation of the equipment.

2. Properly Control Filtration Pressure

The Relationship between Pressure and Filtration Rate

During the operation of a Chamber Filter Press, filtration pressure is a key factor influencing filtration efficiency. While excessive pressure can accelerate solid-liquid separation, it can also damage the filter cloth, cause filtrate loss, and allow solid particles to re-enter the filter chamber, compromising separation efficiency. Excessively low pressure, on the other hand, can slow filtration and even prevent complete separation of solids and liquids. Proper pressure setting is crucial to ensuring effective filtration.

Stage-Based Pressurization

When processing certain materials, a single filtration pressure may not meet efficiency requirements. To optimize the filtration process, a staged pressurization method can be used. Initially, low pressure is applied for initial filtration, then the pressure is gradually increased to adapt to the filtration requirements of the material at each stage. This method reduces the burden on the filter cloth and improves solid-liquid separation efficiency.

3. Optimize the Feed Rate

Control the Feed Amount

A feed rate that is too fast can lead to excessive solids accumulation in the filter chamber, exceeding the filter cloth's filtration capacity and resulting in incomplete solid separation. A feed rate that is too slow can result in prolonged filtration cycles, wasting time and energy. Proper control of the feed amount is crucial to ensuring optimal filtration results. Generally, the optimal feed rate should be determined based on the material properties, the filter chamber volume, and the maximum processing capacity of the equipment.

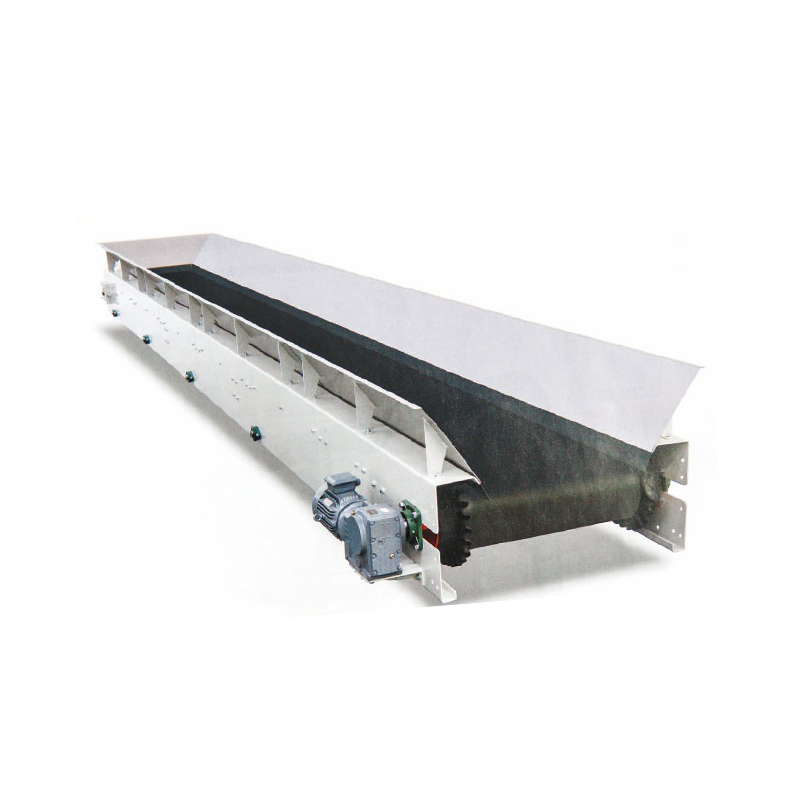

Evenly Distribute the Feed

Uneven feed can lead to excessive pressure in certain filter chambers, affecting overall filtration performance. By optimizing the feed system and ensuring even feed distribution, overloading of certain filter chambers can be effectively avoided. This can be achieved using a feed distributor or regulating valve, thereby improving the efficiency and stability of the entire filtration process.

4. Use Appropriate Filter Aids

Selecting Filter Aids

Filter aids, such as flocculants and coagulants, are important additives for improving solid-liquid separation efficiency. Filter aids accelerate the solid-liquid separation process by agglomerating fine particles into larger ones. Different materials require different filter aids. For example, for wastewater containing grease, flocculants can help separate oil and water; for mineral filtration, coagulants can accelerate the settling of solid particles.

Additive Amount

Excessive filter aid may clog the filter cloth, negatively impacting filtration efficiency. The additive dosage should be adjusted based on test results. Excessive filter aid not only wastes resources but also may result in increased sludge production. Typically, the optimal dosage is gradually found through repeated additions of small amounts to ensure effective filtration while minimizing material waste.

5. Filtration Cycle Management

Filtration Time Control

The length of the filtration cycle is closely related to factors such as pressure, feed rate, and material properties. Excessive filtration time may lead to excessive separation of liquid and solids, resulting in an overly dry filter cake and making subsequent processing difficult. Excessive filtration time may prevent effective solid-liquid separation, compromising filtration efficiency. Therefore, proper control of the filtration cycle is crucial. The filtration time can be dynamically adjusted based on factors such as material viscosity and solids content.

Periodic Replacement of Filter Discs and Plates

Filter discs and plates can become worn, fouled, or deformed over time, leading to reduced filtration efficiency. The condition of the filter plates and discs should be inspected regularly and replaced as necessary. Damage to the filter plates can cause liquid leakage or uneven solids distribution, affecting filtration efficiency. Regular replacement of the filter plates ensures efficient operation and extends the life of the equipment.

6. Regular Maintenance and Inspection

Mechanical Fault Inspection

The mechanical components of the equipment, such as the hydraulic system and pump system, may malfunction over time, affecting filtration efficiency. Regular inspection and maintenance of these mechanical components can identify and correct potential problems promptly. For example, insufficient pressure in the hydraulic system can result in incomplete filtration, while a blockage in the pump system can affect feed flow. Therefore, a detailed inspection and maintenance plan should be developed to ensure that the equipment is in optimal working condition.

Cleaning the System Maintenance

System cleanliness is equally important. Impurities and sediment in the filtrate can clog the drain system or feed lines, affecting the filtration process. Regular cleaning of components such as the hydraulic system, drain lines, and feed lines ensures smooth system operation and prevents clogging that can reduce filtration efficiency. Regular cleaning can significantly reduce equipment failures and extend its service life.

7. Temperature and Environmental Control

The Impact of Temperature on Filtration

Temperature is another key factor affecting filtration effectiveness. Low temperatures increase the viscosity of liquids, slowing filtration. High temperatures may cause chemical changes in some materials, affecting separation. Therefore, maintaining an appropriate operating temperature is crucial for improving filtration efficiency. Generally, when handling liquids, a suitable temperature helps reduce viscosity, facilitating smoother solid-liquid separation.

Ambient Humidity

Excessive humidity can cause mold or corrosion in filter cloth, shortening its service life. In high humidity environments, filter cloth fibers may absorb water and swell, resulting in reduced filtration effectiveness. To avoid this, maintain an appropriate ambient humidity and regularly inspect the condition of the filter cloth to prevent equipment damage caused by excessive humidity.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt