How Does a Filter Press Contribute to Sustainable Practices in Waste Management?

2025.06.23

2025.06.23

Industry News

Industry News

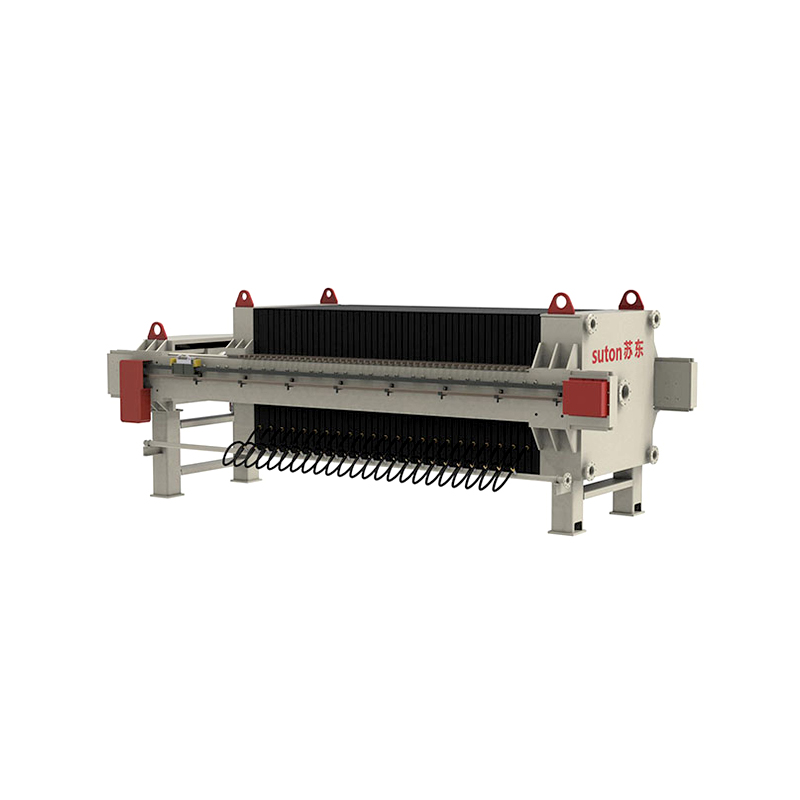

A filter press is a crucial piece of equipment in waste management, especially when it comes to industries dealing with wastewater, sludge, or other by-products that require treatment. Its role in sustainable practices lies in its ability to optimize waste treatment processes, reduce environmental impact, and promote resource recovery.

In industrial settings, waste management often involves dealing with liquid waste streams containing both solids and contaminants. Without proper filtration, these materials can pose a serious risk to the environment, potentially polluting water bodies, soil, and air. The filter press contributes to sustainability by effectively separating solids from liquids, ensuring that the contaminants can be removed or concentrated in a manner that reduces their negative impact on the environment. This means that, rather than disposing of large quantities of untreated waste, industries can manage their waste streams more effectively, ensuring that harmful pollutants are isolated and that fewer contaminants are released into the environment.

One of the primary advantages of using a filter press is its ability to recover clean water from waste materials. By separating out the solid contaminants, the filter press leaves behind relatively clear water that can often be reused in the industrial process. This reuse of water is a significant contribution to water conservation, which is a critical element of sustainability, especially in industries that require vast amounts of water. Instead of relying on freshwater sources or external water treatment facilities, industries can cycle water back into their systems, reducing the need for external water resources and decreasing operational costs.

Mhe filter press plays an essential role in the reduction of harmful contaminants in wastewater. In many industries, wastewater may contain toxic substances such as heavy metals, chemicals, oils, or other hazardous materials. By concentrating these harmful substances in the solid filter cake, the filter press prevents them from contaminating natural water sources or being released into the environment. This helps safeguard ecosystems, particularly aquatic life, and ensures that industries meet environmental standards that protect public health.

A crucial aspect of the filter press’s contribution to sustainability is its ability to minimize the volume of waste that needs to be disposed of. Traditional waste management methods often involve sending large amounts of sludge or liquid waste to landfills or incineration facilities, both of which have significant environmental impacts. The filter press reduces the volume of waste by concentrating it into a dry, solid cake, which can be handled more efficiently and cost-effectively. This means less waste is sent to landfills, thus extending the lifespan of landfill sites and reducing the environmental footprint of waste disposal.

The filter press is energy-efficient compared to many other methods of waste treatment. Traditional processes such as thermal drying or centrifugation can consume large amounts of energy, while the filter press relies primarily on mechanical pressure. This lower energy consumption contributes to a smaller carbon footprint, making it a more eco-friendly option for industries looking to reduce their energy usage and environmental impact.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt