How does Filter Press improve the efficiency of solid-liquid separation in industrial production processes?

2025.05.06

2025.05.06

Industry News

Industry News

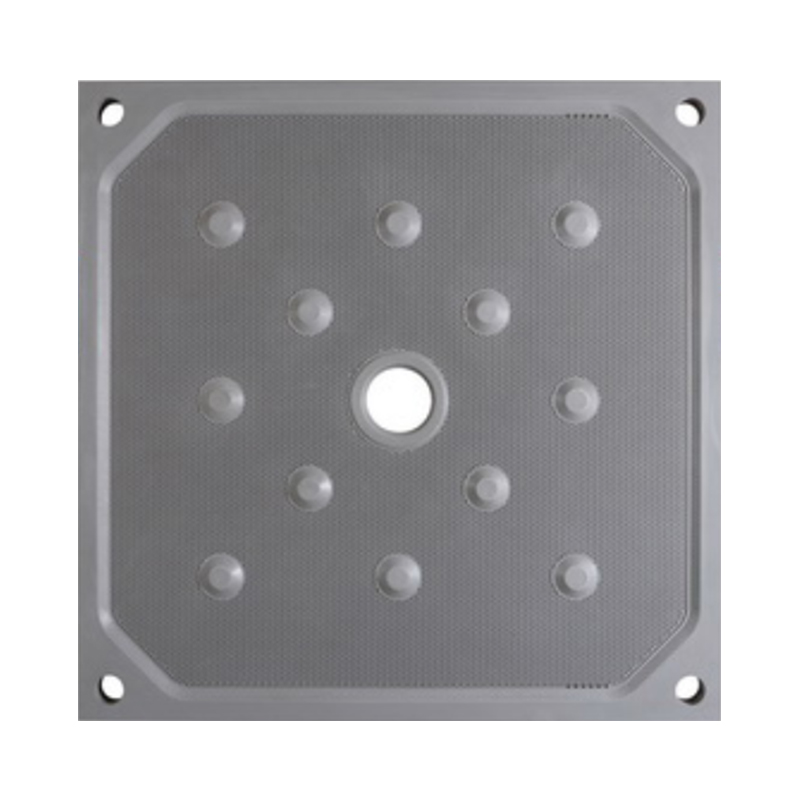

The Filter Press accelerates the solid-liquid separation process by operating under high pressure. The basic working principle is that the liquid is forced to be pressurized through the filter cloth, the solid particles are trapped on the filter cloth, and the clear liquid is discharged from the other side. Compared with traditional gravity filtration or centrifugal separation, the Filter Press can achieve filtration in a shorter time at higher pressure. This high pressure not only speeds up the separation process, but also significantly improves the retention efficiency of solid particles, thereby ensuring high purity of the liquid. Its solid-liquid separation effect is more refined than many other devices, especially suitable for production environments that require high-precision separation.

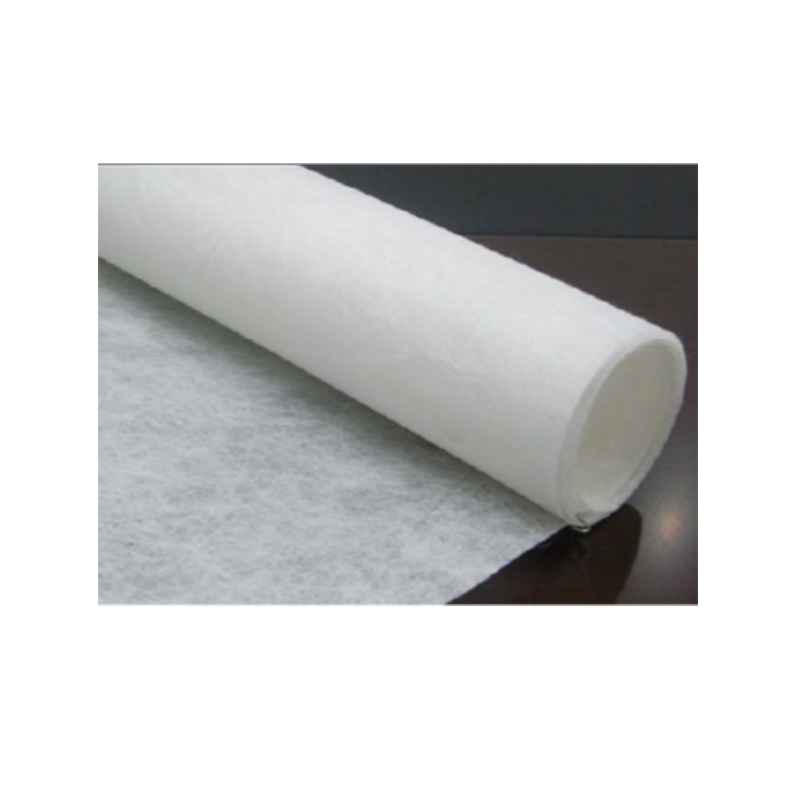

Another important advantage of the Filter Press is the selectivity and adaptability of its filter cloth. According to different production requirements, filter cloths of different materials and pore sizes can be selected to accommodate solid particles of different sizes and shapes. The customized design of the filter cloth allows the Filter Press to be optimized for specific materials to ensure that it can provide ideal solid-liquid separation effects under different working conditions. For example, for liquids containing fine particles, the Filter Press can effectively separate these small particles through the fine filter cloth pore design to ensure high cleanliness of the liquid. The replaceability and diversity of this filter cloth enable the Filter Press to play a role in a wide range of industrial applications, whether it is processing large-particle materials or fine-particle liquids, it can achieve the best separation effect.

In the solid-liquid separation process, the Filter Press not only focuses on the separation effect, but also on how to reduce the residual liquid. Its design concept emphasizes the maximum discharge of liquid by applying pressure to reduce the water content of the filter cake. This feature enables the Filter Press to handle a large amount of solid waste while reducing the discharge of waste liquid, which not only improves work efficiency but also effectively meets environmental protection requirements. When many industries treat wastewater, they pay special attention to the removal of solid matter in wastewater. The efficient solid-liquid separation ability of the Filter Press enables wastewater discharge to meet the environmental protection standards of the industry, thereby avoiding environmental pollution caused by excessive wastewater.

Modern Filter Press is also widely equipped with automated control systems, which makes its operation easier and more reliable. The application of automation technology can not only automatically adjust the filtration process, but also realize full automation in filter plate cleaning, slag discharge and other links, thereby greatly improving production efficiency. Compared with traditional manual operation, the automation function reduces the need for manual intervention, improves operation accuracy, and reduces the risk of human error. In many large production lines, the automated system of the Filter Press can run continuously and stably, thus ensuring an efficient and seamless solid-liquid separation process.

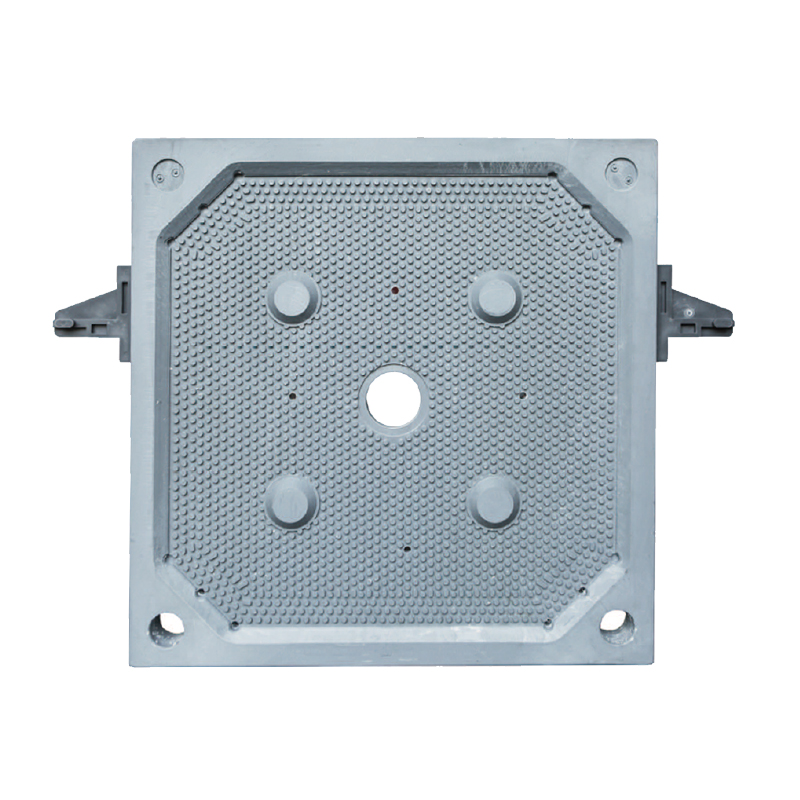

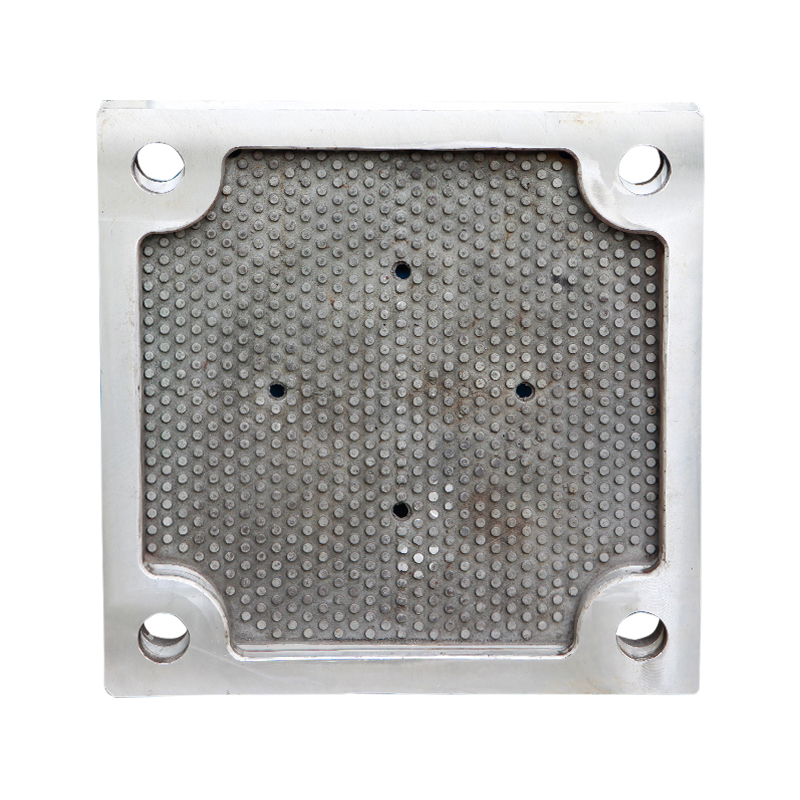

The high processing capacity of the Filter Press is also one of its significant advantages. It can process a large amount of material in a short time, which is particularly suitable for industrial production environments that require large-capacity solid-liquid separation. The Filter Press can process multiple batches of liquid at the same time through the combination of multiple filter plates, which not only speeds up the production process, but also significantly improves the overall production efficiency. Whether it is processing ore pulp in the mining industry or in the process of chemical wastewater treatment, the high efficiency of the Filter Press can ensure the continuous operation of the production line and avoid production stagnation caused by incomplete solid-liquid separation.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt