What Are the Common Applications of Plate and Frame Filter Press in Industry?

2025.05.12

2025.05.12

Industry News

Industry News

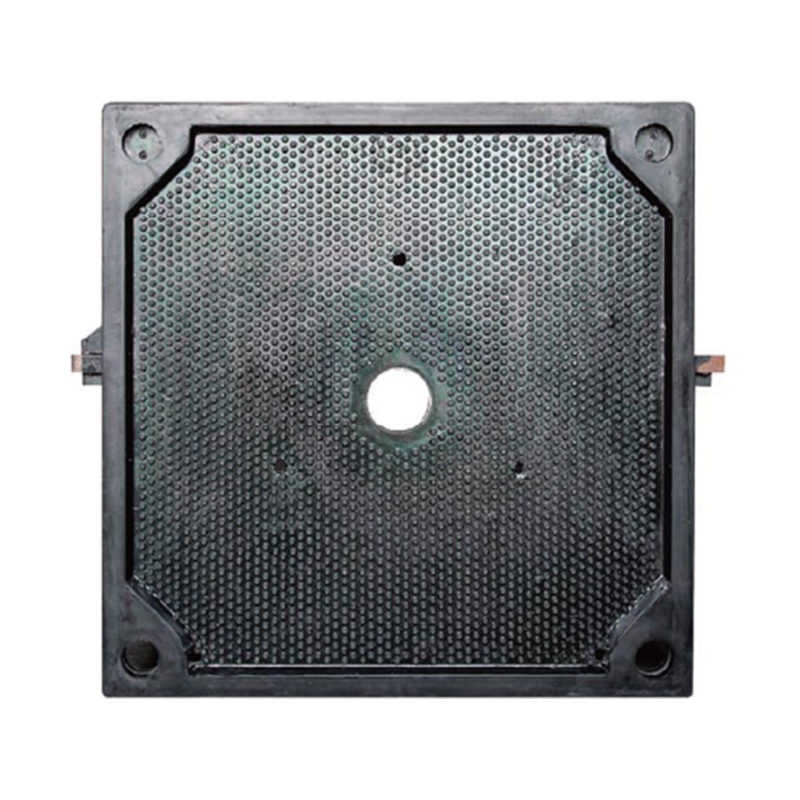

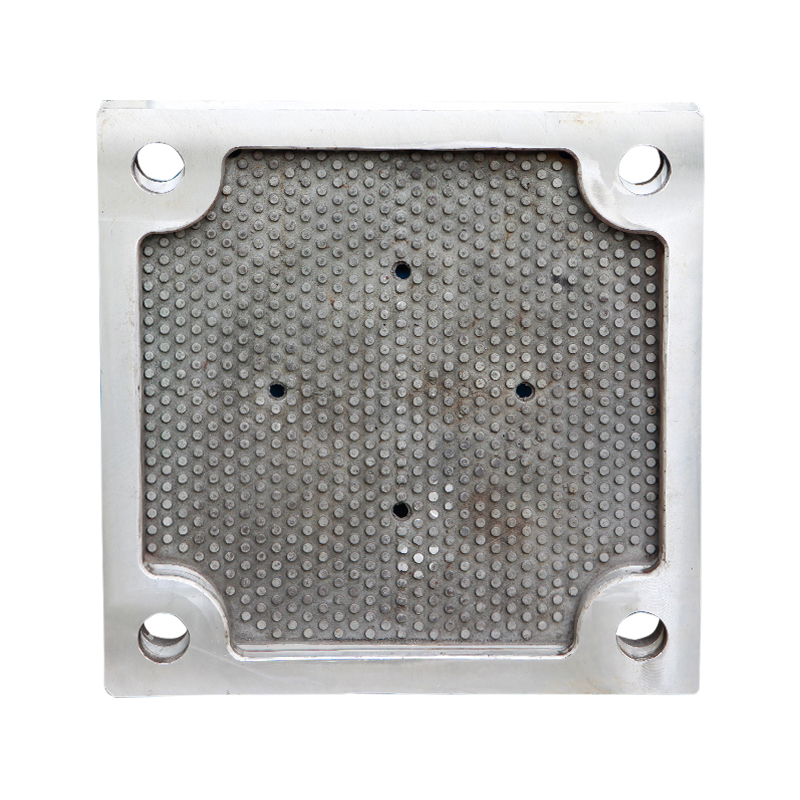

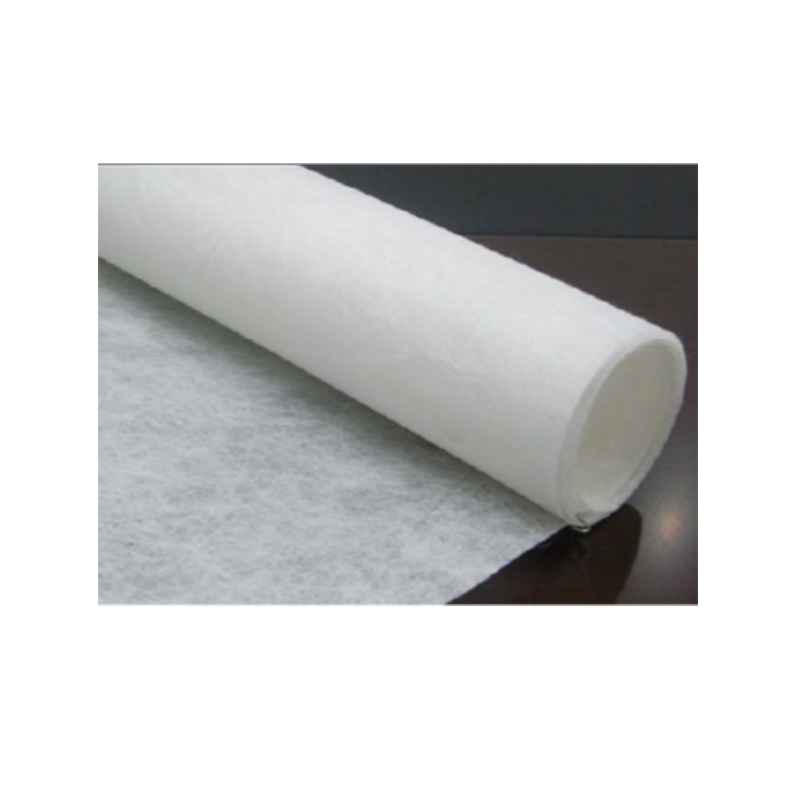

Plate and frame filter presses are versatile filtration devices widely used across various industries for liquid-solid separation. These systems consist of multiple filter plates arranged alternately with frames that hold a filtering medium, such as cloth, through which a liquid is passed to separate suspended solids. The liquid flows through the filters, while the solids are trapped, and the filtered liquid is discharged. This technology plays a crucial role in a variety of industrial processes, each with its own set of demands and requirements.

In the mining and metallurgy industries, plate and frame filter presses are indispensable for the dewatering of slurries, particularly when dealing with mining tailings and concentrates. In these applications, the presses help separate valuable minerals from waste materials, thereby optimizing mineral recovery. This process not only maximizes the extraction of usable materials but also minimizes the volume of waste that needs to be handled and disposed of. The ability to recycle water is another significant advantage, contributing to more sustainable operations. The versatility of the filter press in dealing with high-viscosity slurries makes it ideal for such demanding environments.

In the chemical industry, plate and frame filter presses are used to filter a broad range of chemicals, including acids, bases, and solvents, to remove unwanted solids and clarify liquids. These presses are crucial in maintaining the purity of chemicals and ensuring the quality of products. For example, when dealing with viscous fluids, the filter press’s ability to handle high-solid loads and produce a clarified product is vital. The use of filter presses in chemical production is not limited to large-scale operations; they are also common in laboratories and small-scale chemical processes that require high levels of filtration efficiency.

The food and beverage industry also benefits from the use of plate and frame filter presses, particularly in processes like juice clarification, oil filtering, and syrup purification. In juice production, the press removes pulp and other solids from the liquid to ensure that the juice is smooth and free of any unwanted particles. Similarly, in the production of olive oil, plate and frame filter presses are used to separate solid residues from the oil, resulting in a higher-quality, clearer product. In syrup production, such as maple syrup, these filters help maintain the clarity and consistency of the final product by removing impurities that could affect its flavor or texture. These applications show the filter press's ability to handle liquids in a variety of viscosities and ensure that food products meet industry standards for purity.

The pharmaceutical industry relies heavily on plate and frame filter presses for the production of high-purity medicines and chemicals. During the manufacture of antibiotics, vaccines, and other pharmaceutical products, the need for sterile and impurity-free solutions is critical. The filter press ensures that any suspended solids are effectively removed from the liquids, contributing to the production of high-quality, safe medicines. Because of the strict regulatory requirements in the pharmaceutical industry, these filtration systems are designed to meet stringent standards for cleanliness, reliability, and performance.

In municipal and industrial water treatment plants, plate and frame filter presses are essential for treating wastewater and separating suspended solids. The filtration process allows for the recovery of clean water that can be reused in various industrial processes or safely discharged into the environment. By efficiently removing contaminants from water, these filter presses play a key role in helping industries comply with environmental regulations, reducing the risk of contamination, and minimizing the environmental impact of industrial operations.

In the oil and gas industry, these filter presses are used for filtering drilling muds, oils, and water used in exploration and drilling activities. The high volumes of fluid and solid waste generated during drilling operations require effective filtration systems to manage and treat the waste. Plate and frame filter presses help ensure that drilling fluids are purified and can be reused in subsequent drilling activities. They are critical in preventing the contamination of the surrounding environment by efficiently separating harmful solids from liquids and helping dispose of waste in an environmentally responsible manner.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt