What Are the Common Problems with Filter Press Plates and How to Fix Them?

2025.12.29

2025.12.29

Industry News

Industry News

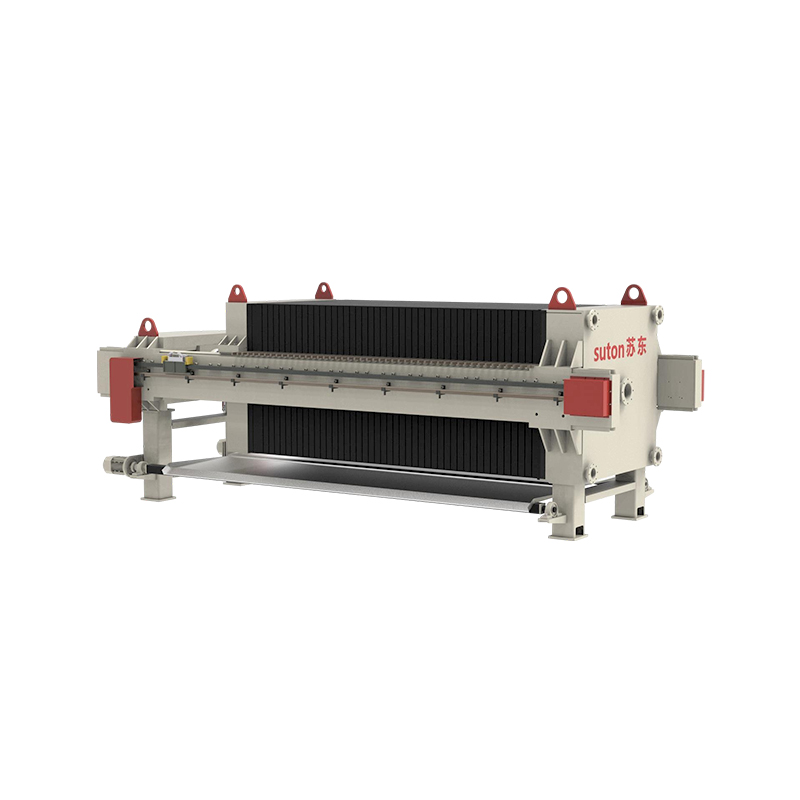

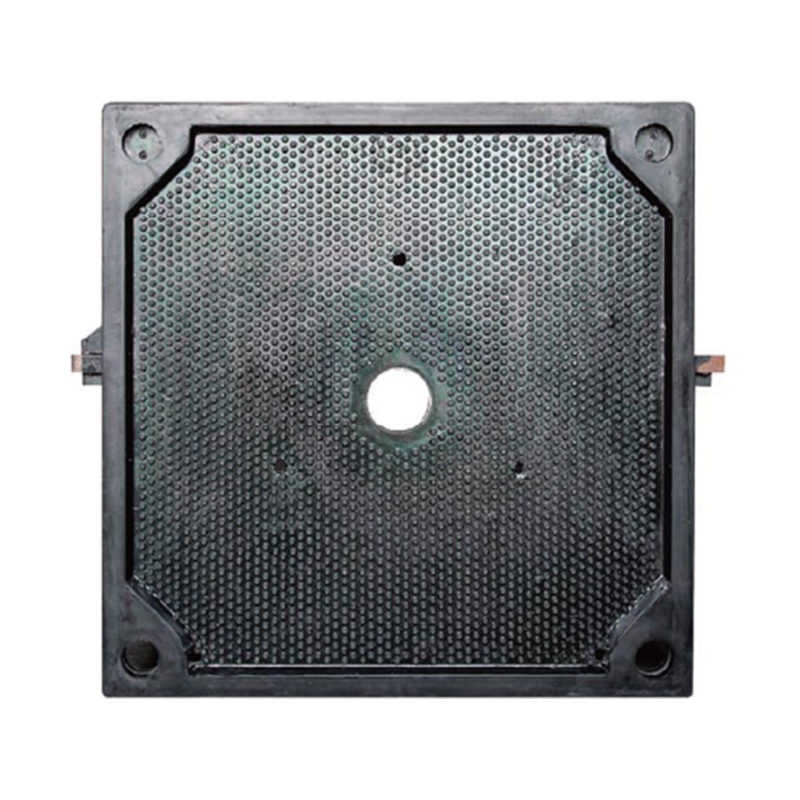

Filter press plates are critical components used in various industrial applications such as wastewater treatment, chemical processing, and food industries. They are responsible for separating solid particles from liquids by creating a pressure-driven filtration process.

1. Plate Leakage

Problem: Leakage is one of the most common issues with filter press plates. It happens when the sealing mechanism between the plates fails, allowing the slurry to escape. This leads to cross-contamination, product loss, and inefficient filtration.

Cause: The main cause of leakage is worn-out gaskets or seals, improper alignment of the plates, or incorrect tightening of the plate stack.

Fix:

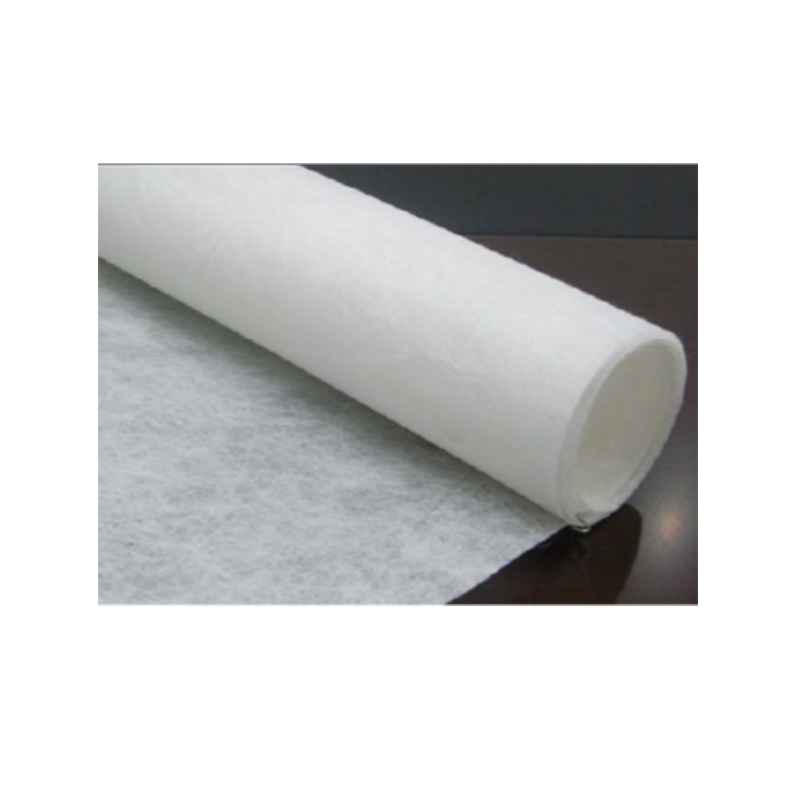

- Check Gaskets: Inspect the gaskets around each plate for signs of damage, cracks, or wear. If any gaskets are compromised, replace them immediately.

- Proper Alignment: Ensure that the filter press plates are aligned properly during installation and maintenance. Misalignment can cause uneven sealing.

- Tightening: Ensure the plates are tightened correctly according to the manufacturer’s recommendations. Over-tightening or under-tightening can affect the sealing pressure.

2. Plate Clogging

Problem: Clogging occurs when the filter press plates become blocked with solids, which reduces the filtration efficiency and causes delays in the dewatering process.

Cause: Clogging often results from the presence of fine particles in the slurry that build up over time. Poor slurry feed distribution or excessive solids in the material can also contribute to clogging.

Fix:

- Regular Cleaning: Clean the filter press plates periodically using high-pressure water jets or appropriate cleaning chemicals. This helps remove accumulated solids and ensures a smooth filtration process.

- Backwashing: In certain applications, backwashing or reverse flow cleaning is recommended to help dislodge trapped particles.

- Proper Feed Distribution: Ensure that the slurry is evenly distributed across the plates to avoid uneven cake formation and clogging.

3. Uneven Cake Formation

Problem: When filter cakes do not form uniformly, it leads to inefficient filtration, lower throughput, and suboptimal separation of solids from liquids.

Cause: Uneven cake formation can be caused by irregular slurry feed, inconsistent pressure, or worn-out filter plates that don’t maintain even contact.

Fix:

- Optimized Pressure: Ensure that the filtration pressure is within the recommended range. Too high or too low a pressure can cause uneven cake formation.

- Slurry Flow Control: Control the slurry feed rate and ensure it is uniform across the plate surface to ensure even distribution.

- Check for Worn Plates: Inspect the filter plates regularly for damage or wear. Replace any plates that no longer function correctly.

|

Problem |

Cause |

Fix |

|

Plate Leakage |

Worn gaskets, misalignment |

Replace gaskets, align plates, proper tightening |

|

Plate Clogging |

Fine solids, poor distribution |

Clean plates, backwash, proper slurry feed |

|

Uneven Cake Formation |

Irregular slurry feed, pressure inconsistency |

Optimize pressure, check for worn plates |

4. Damage to Plate Edges

Problem: Filter press plates can suffer damage, such as cracks or chips along the edges, which can result in inefficient filtration or leaks.

Cause: Physical damage during handling, abrasive particles in the slurry, or excessive pressure can cause the edges of the plates to crack or become damaged.

Fix:

- Inspect Plates Regularly: Perform visual inspections to check for any cracks or chips around the edges of the plates.

- Handle with Care: Train personnel to handle the plates gently during installation or maintenance to prevent accidental damage.

- Replace Damaged Plates: Any plates that are cracked or chipped should be replaced immediately to avoid further damage or performance issues.

5. Warping or Bowing of Plates

Problem: Warping or bowing of the plates can affect the sealing and alignment of the filter press, reducing its efficiency and causing uneven pressure distribution.

Cause: This often results from excessive pressure, high temperatures, or faulty manufacturing. Plates may also warp over time due to prolonged exposure to harsh conditions.

Fix:

- Monitor Pressure: Ensure that the pressure used in the filtration process is within the manufacturer’s recommended limits. Over-pressurizing can warp the plates.

- Temperature Control: Maintain consistent operating temperatures. Extreme temperature fluctuations can cause materials to expand or contract unevenly, leading to warping.

- Replace Warped Plates: If the plates are warped beyond repair, they need to be replaced to ensure the filter press operates efficiently.

6. Improper Plate Alignment

Problem: Misalignment between the plates can cause incomplete sealing, resulting in leakage and reduced filtration efficiency.

Cause: Plate misalignment typically occurs during installation or after extended use due to wear on the frame or the plates themselves.

Fix:

- Check Plate Alignment Regularly: Before operating the filter press, check that all plates are aligned correctly. Misaligned plates will prevent the filter press from functioning properly.

- Proper Installation: During installation or maintenance, make sure the plates are aligned properly and are free from debris or foreign objects that could cause misalignment.

- Frame Maintenance: Check the frame of the filter press for any wear or damage that might cause misalignment and repair it if necessary.

7. Corrosion of Filter Press Plates

Problem: Over time, filter press plates exposed to harsh chemicals or extreme conditions may corrode, leading to reduced filtration performance and possible contamination of the filtrate.

Cause: Corrosion is caused by exposure to acidic or alkaline materials, or cleaning agents that are too harsh for the materials the plates are made from.

Fix:

- Corrosion-Resistant Materials: If your process involves corrosive materials, consider using filter plates made from corrosion-resistant materials like polypropylene or stainless steel.

- Proper Cleaning: Use appropriate, mild cleaning chemicals and avoid using corrosive agents that can damage the plate surface.

- Regular Inspection: Inspect the plates frequently for signs of corrosion, and replace any affected plates before they compromise the filtration process.

8. Sticking or Difficulty in Plate Separation

Problem: After a filtration cycle, the filter press plates can sometimes stick together, making it difficult to separate them for cleaning or replacement.

Cause: This is often caused by filter cake build-up between the plates, particularly when the slurry material hardens or solidifies between the plates.

Fix:

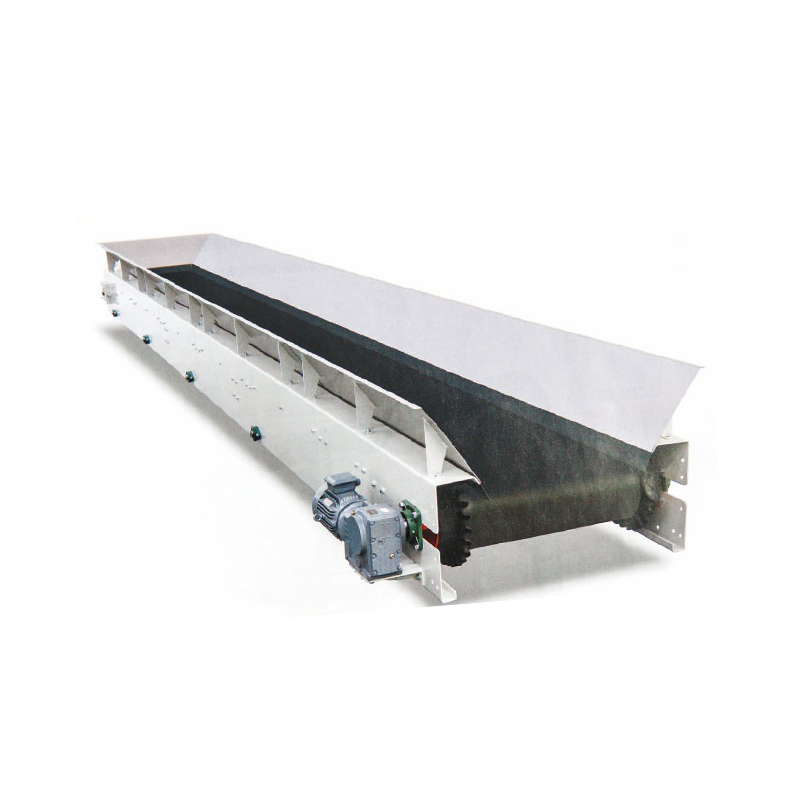

- Shaking Mechanism: Use a plate shaking mechanism to help release the plates after each cycle. This can help reduce the risk of them sticking together.

- Periodic Cleaning: Clean the plates between cycles to prevent cake build-up.

- Lubrication: Apply suitable lubricants to the plate edges to facilitate easier separation.

9. Inconsistent Filtrate Quality

Problem: If the filtrate is cloudy, contains suspended solids, or doesn’t meet quality standards, it indicates an issue with the filter press plates or the filtration process.

Cause: The issue may arise from damaged or worn-out plates that allow unfiltered material to pass through, improper pressure settings, or an incorrectly calibrated feed.

Fix:

- Inspect for Damage: Examine the filter plates for wear, cracks, or deformation. Any plates that are compromised should be replaced.

- Optimize Pressure: Ensure the pressure settings are correct and consistent during the filtration process. Too high or too low pressure can impact filtrate quality.

- Feed Calibration: Ensure that the slurry feed is calibrated correctly, and adjust the flow rate if necessary.

10. Reduced Filtration Efficiency

Problem: Over time, the filtration efficiency of a filter press may decrease, resulting in longer cycle times, lower throughput, and reduced separation performance.

Cause: Reduced efficiency can be due to clogged plates, damaged gaskets, or improper operating conditions.

Fix:

- Regular Maintenance: Clean the plates and gaskets regularly, and check for any wear or damage.

- Optimize Filtration Parameters: Adjust the feed rate, pressure, and filtration cycle times to ensure optimal performance.

- Replace Worn Components: If the plates or gaskets are damaged or worn, replace them immediately to restore filtration efficiency.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt