What Is a Diaphragm Filter Press and How Does It Work?

2025.12.15

2025.12.15

Industry News

Industry News

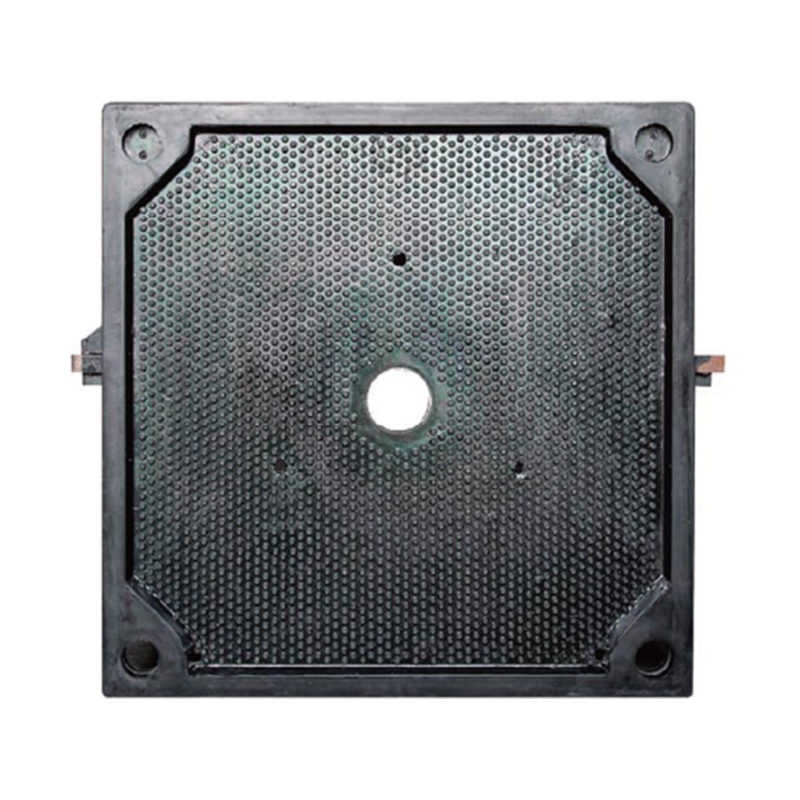

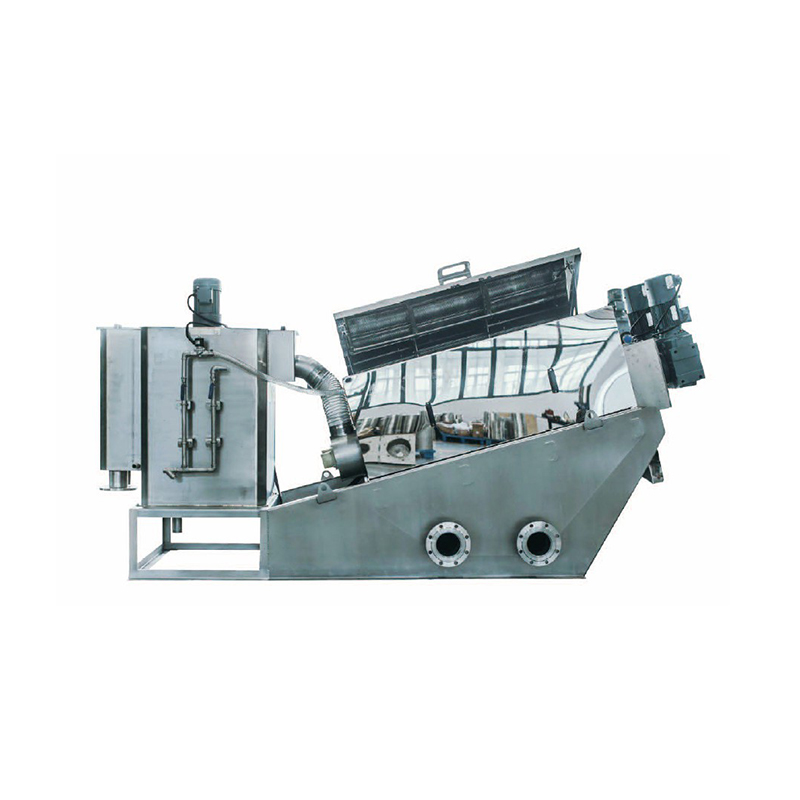

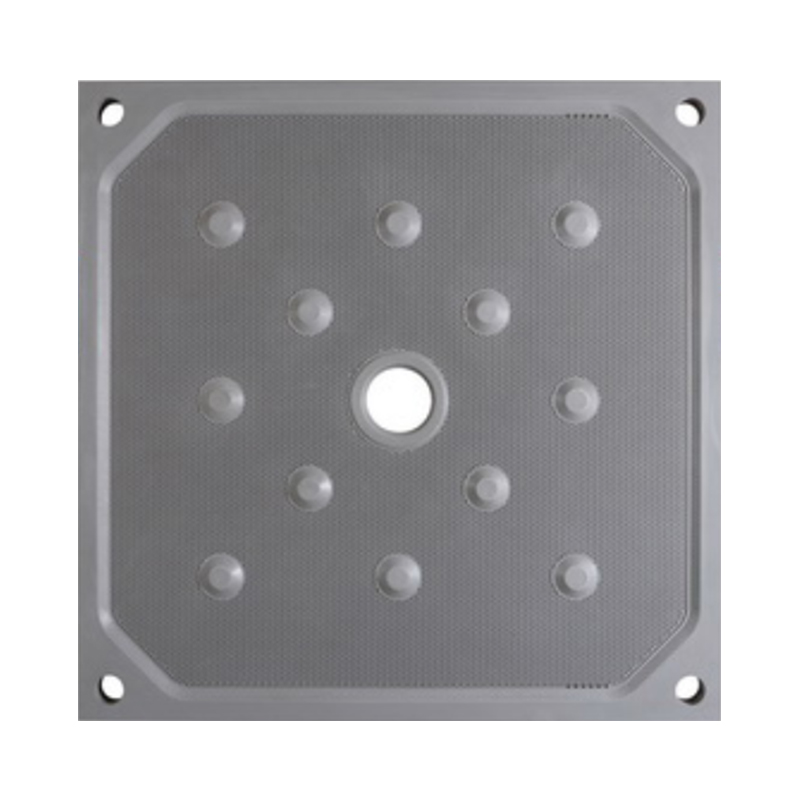

A Diaphragm Filter Press is an advanced type of filtration equipment designed to separate solid particles from liquids in various industrial applications. It utilizes a unique diaphragm at the rear of each filter plate, which improves the dewatering process by applying extra pressure to the solid cake, resulting in drier solids.

How Does a Diaphragm Filter Press Work?

The operation of a diaphragm filter press is similar to that of a traditional filter press, but with a crucial difference—the inclusion of a flexible diaphragm. This diaphragm plays a significant role in the filtration process, especially during the final dewatering stage.

Let’s break down the process:

Slurry Introduction: The slurry (a mixture of liquids and solids) is pumped into the filter press. This slurry enters a stack of filter plates separated by filter cloths or membranes, which act as the filtration medium.

Filtration Phase: The slurry is subjected to pressure (usually between 6-16 bar). The liquid part of the slurry passes through the filter medium, while the solid particles are trapped inside the filter plate chambers. This phase results in the formation of a filter cake inside the press, which consists of the solid particles.

Diaphragm Inflation (Final Dewatering): After the filtration phase, the filter press enters the diaphragm dewatering stage. The diaphragm, located at the rear of each filter plate, is inflated with water or air. As the diaphragm inflates, it exerts additional pressure on the filter cake, squeezing out the remaining liquid trapped within the solids. This step is critical because it results in a drier filter cake, which is more manageable for disposal or further processing.

Cake Discharge: Once the diaphragm has exerted pressure and removed excess liquid, the filter plates are separated, and the solid filter cakes are removed from the press. These cakes are typically much drier than those produced by conventional filter presses, making them easier to handle.

Key Features and Benefits of Diaphragm Filter Press

|

Feature |

Diaphragm Filter Press Benefits |

|

Additional Pressure from Diaphragm |

Increased cake dryness, resulting in reduced waste volume and disposal costs. |

|

Enhanced Filtration Efficiency |

Improved separation of solids and liquids, leading to cleaner filtrate. |

|

High Operating Pressure |

Achieves faster filtration and better overall throughput. |

|

Automated Operation |

Reduces human intervention and lowers labor costs. |

|

Lower Energy Consumption |

Efficient operation leads to lower energy usage compared to other presses. |

Drier Cakes: The diaphragm’s additional pressure ensures that the solids are dewatered more effectively, leading to drier cakes. This is particularly important for industries where the disposal of sludge or cake is a major concern. The drier the cake, the lower the costs for disposal or further processing.

Higher Efficiency: The added pressure from the diaphragm helps improve the overall filtration process, making it more efficient. This is especially beneficial in applications where a high throughput is needed.

Reduced Operating Costs: With higher filtration efficiency and drier cakes, diaphragm filter presses can help reduce operating costs in the long term. This includes savings on maintenance, energy usage, and waste disposal.

Environmental Impact: The drier filter cake produced by diaphragm filter presses also contributes to a reduced environmental footprint, as it requires less energy and resources to dispose of or treat.

Applications of Diaphragm Filter Presses

Diaphragm filter presses are used in a variety of industries, where effective filtration is crucial for product quality, process efficiency, and waste reduction. Some common applications include:

Wastewater Treatment: Diaphragm filter presses are extensively used in municipal and industrial wastewater treatment plants to dewater sewage sludge and other wastewater by-products. The resulting solid cake is easier to dispose of or can be further treated.

Mining: In the mining industry, diaphragm filter presses are used to separate valuable minerals from slurry. The filtration process helps extract metals like gold, silver, and copper while minimizing waste.

Chemical Industry: Chemical manufacturers use diaphragm filter presses to separate solids from liquids in various chemical processes. This is particularly important in the production of products such as acids, detergents, and solvents.

Food and Beverage: In the food industry, diaphragm filter presses are used to filter liquids like fruit juices, wine, and edible oils. This ensures a clean, pure product while removing unwanted particles.

Pharmaceutical Industry: The pharmaceutical sector uses diaphragm filter presses to separate active ingredients from solvents or other media, ensuring that high-quality products are delivered.

Advantages Over Conventional Filter Presses

Compared to traditional plate and frame filter presses, diaphragm filter presses offer several key advantages:

Better Filtrate Quality: The additional dewatering process provided by the diaphragm leads to cleaner filtrate, which is an important factor in industries where product purity is critical.

Less Cake Moisture: The diaphragm’s ability to exert pressure during the final phase of filtration results in a significantly drier filter cake, reducing disposal and treatment costs.

Faster Filtration: Due to the higher pressure exerted by the diaphragm, the diaphragm filter press generally operates faster than conventional presses, which increases throughput and productivity.

Reduced Maintenance: Because the diaphragm helps remove more liquid during the dewatering phase, there is less buildup of sludge or residue in the filter, which means fewer cleaning cycles and reduced maintenance costs.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt