Why Is the Chamber Filter Press Considered Essential for Wastewater Treatment?

2025.12.08

2025.12.08

Industry News

Industry News

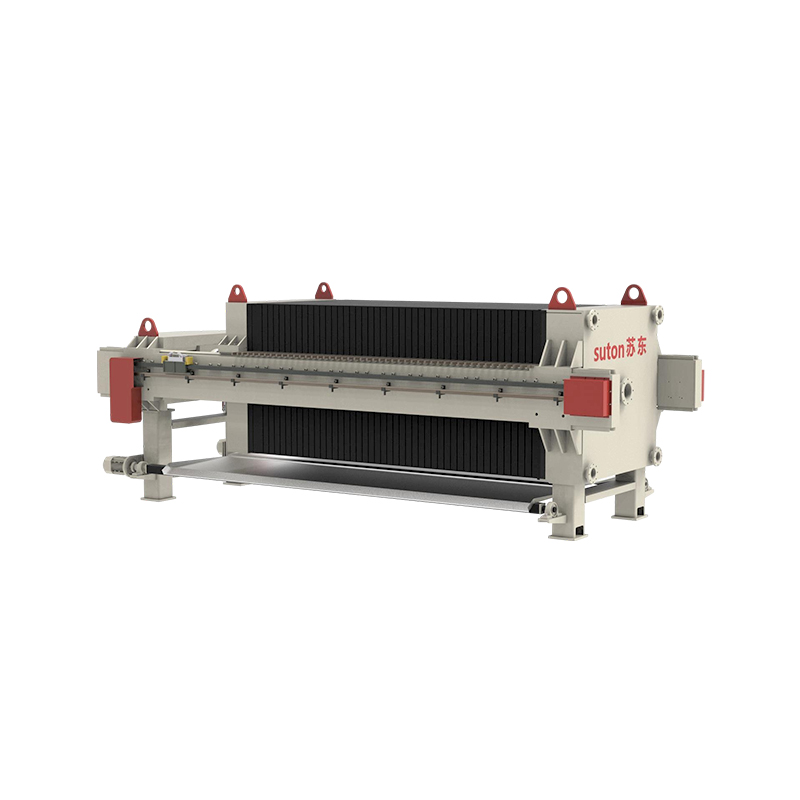

The Chamber Filter Press is a vital piece of equipment in wastewater treatment because of its efficiency, versatility, and the ability to produce high-quality treated water. In industries ranging from manufacturing to mining, it plays a key role in separating solids from wastewater, ensuring the effluent meets environmental standards.

1. Efficient Solid-Liquid Separation

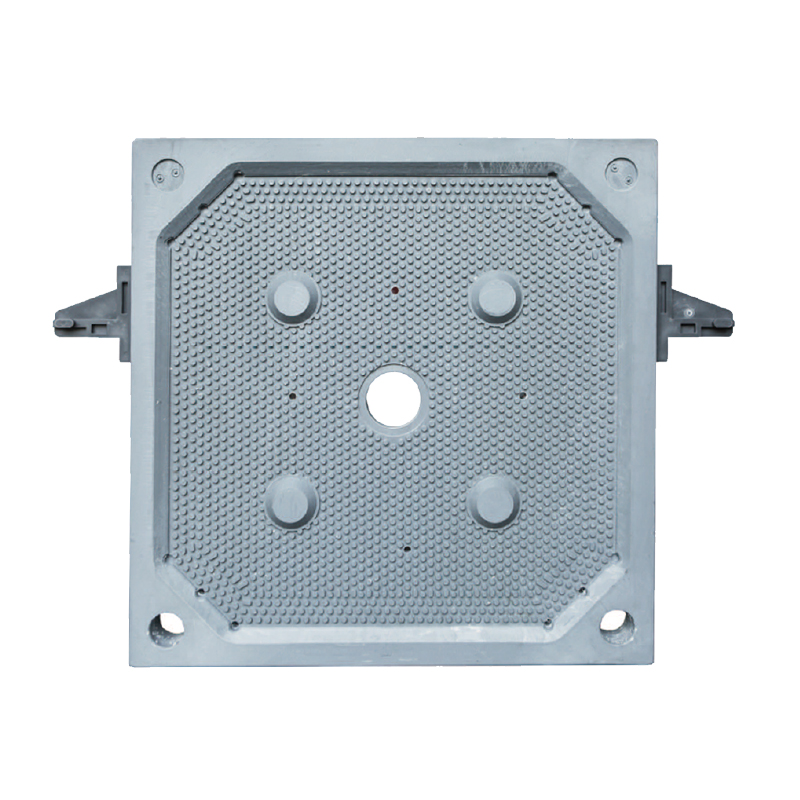

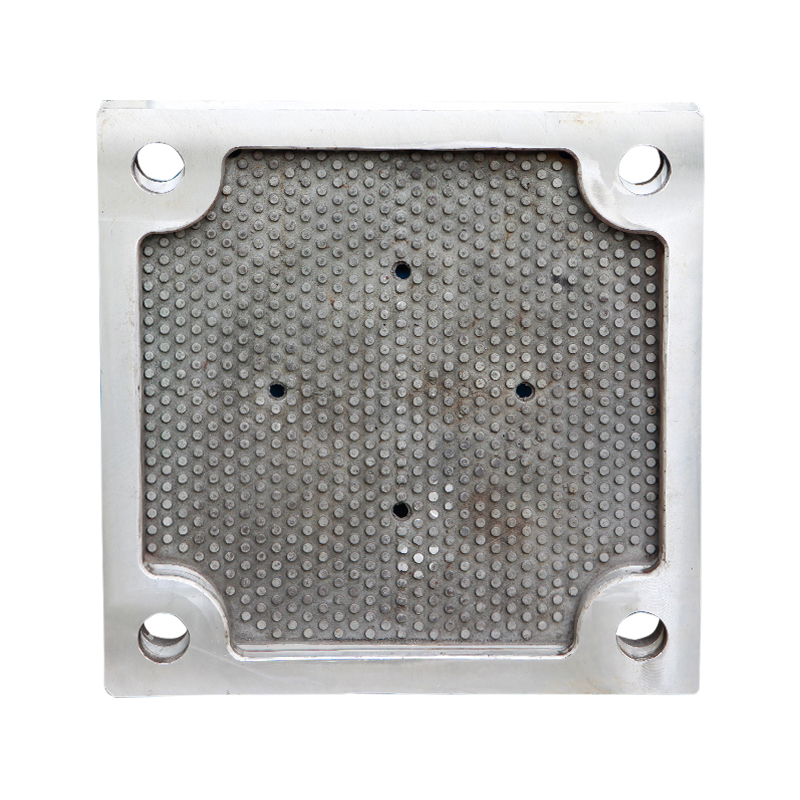

The core function of a Chamber Filter Press is to separate solid particles from liquids. In wastewater treatment, this separation is crucial because the effluent can contain a wide variety of contaminants, such as suspended solids, oils, and chemicals, that need to be removed before discharge. The Chamber Filter Press uses filter cloths and mechanical pressure to capture the solids and allow the liquid to pass through. This process ensures that the treated water is clean and free from harmful pollutants, which is especially important in industries where water quality is strictly regulated.

- How it works: The wastewater is pumped into the filter press, where it is filtered through multiple chambers, and the solid particles are trapped between the filter plates. Clean water is released from the other side, making the system highly efficient.

2. High Filtration Capacity

Chamber Filter Presses are designed to handle large volumes of wastewater. They are capable of treating wastewater from industrial plants, municipal sewage systems, and even agricultural runoffs, making them ideal for high-demand applications. The high filtration capacity of the Chamber Filter Press means that it can process large quantities of effluent in a relatively short period, which is particularly beneficial for industries with high-volume wastewater generation, such as the mining, food processing, and chemical industries.

- Key advantage: For companies with high wastewater generation rates, the Chamber Filter Press allows for continuous operation with minimal downtime, ensuring smooth workflow and consistent filtration performance.

3. Cost-Effective Wastewater Management

One of the biggest advantages of the Chamber Filter Press is its cost-effectiveness. It offers a lower total cost of ownership compared to other filtration technologies. This is because the filter press requires fewer chemicals, consumes less energy, and requires less maintenance. In addition, it reduces the need for extensive waste treatment chemicals that would otherwise increase operational costs. Furthermore, the solid waste (sludge) produced during filtration can be disposed of more easily, which also lowers disposal costs.

- Operational savings: By reducing the reliance on chemicals and providing long-term durability, Chamber Filter Presses significantly cut down on both capital and operational expenditures.

4. Improvement of Water Quality

Water quality is critical in industries where treated water is reused or discharged into natural water bodies. The Chamber Filter Press excels in improving water quality by efficiently removing suspended solids and other contaminants. This ensures that the treated effluent meets the stringent standards required for environmental compliance.

- Achieving compliance: Wastewater treatment facilities must adhere to regulations regarding the maximum allowable levels of suspended solids, turbidity, and other pollutants. Chamber Filter Presses can filter out these contaminants to produce clean water that meets or exceeds regulatory standards.

5. Energy Efficiency

The Chamber Filter Press is designed to be energy-efficient compared to some other filtration methods. It uses mechanical pressure for filtration, which generally requires less energy than chemical processes or other filtration technologies such as membrane filtration or centrifugation. The energy used in the process is concentrated on applying pressure to remove the solids, which maximizes the efficiency of the system.

- Energy savings: Reduced energy consumption not only lowers operational costs but also makes the Chamber Filter Press a more sustainable solution in comparison to other energy-intensive filtration methods.

6. Versatility in Applications

The Chamber Filter Press is highly versatile and can be used across a wide range of industries. These include mining, food processing, chemical manufacturing, paper and pulp, and pharmaceuticals. Each industry generates different types of wastewater, but the Chamber Filter Press can handle various contaminants, from oil and grease to organic waste and heavy metals, making it an indispensable tool for diverse applications.

- Adaptability: Whether the wastewater is highly acidic, alkaline, or contains heavy metals, the Chamber Filter Press can be customized to handle these different challenges, making it an ideal choice for multi-industry applications.

7. Minimal Chemical Usage

Unlike some other wastewater treatment methods that rely heavily on chemicals for coagulation and flocculation, the Chamber Filter Press uses minimal chemicals, primarily in the form of flocculants. This makes the system more environmentally friendly and safer to operate. By reducing the amount of chemicals used, it also lowers the risks associated with chemical handling and disposal.

- Eco-friendly solution: Reducing the chemical load in wastewater treatment not only minimizes the environmental impact but also cuts down on chemical purchasing and storage costs.

8. Compliance with Environmental Regulations

Many industries are subject to strict environmental regulations governing the discharge of wastewater. The Chamber Filter Press helps companies meet these regulations by providing high-quality effluent that conforms to local and international discharge standards. It reduces the risk of non-compliance fines and reputational damage caused by poor wastewater management.

- Regulatory compliance: By ensuring that the treated water is of the highest quality, businesses can avoid costly fines, legal issues, and environmental damage.

9. Reduced Sludge Volume

The Chamber Filter Press reduces the volume of sludge created during wastewater treatment. The filtration process dehydrates the sludge, creating a compact cake that is easier to handle and dispose of. This reduction in sludge volume leads to lower disposal costs and minimizes the environmental impact of waste management.

- Sludge management: Compacting sludge also reduces the space required for storage and transport, making it a more sustainable and cost-effective solution for handling industrial waste.

10. Low Maintenance Requirements

Compared to other filtration equipment, the Chamber Filter Press requires relatively low maintenance. The design is simple, with fewer moving parts, which means less wear and tear. Regular cleaning and occasional replacement of filter cloths are typically all that is needed to keep the system running smoothly. The durability and reliability of the Chamber Filter Press make it a long-term investment for wastewater treatment operations.

- Operational longevity: With proper maintenance, a Chamber Filter Press can operate efficiently for many years, offering substantial returns on investment.

Advantages of Chamber Filter Press in Wastewater Treatment:

|

Advantage |

Benefit |

|

Efficient Solid-Liquid Separation |

Produces cleaner water and reduces environmental impact. |

|

High Filtration Capacity |

Capable of handling large wastewater volumes. |

|

Cost-Effective |

Reduces chemical, energy, and maintenance costs. |

|

Improvement of Water Quality |

Ensures compliance with environmental discharge regulations. |

|

Energy Efficiency |

Lower energy consumption compared to other filtration methods. |

|

Versatility |

Adaptable to various industries and wastewater types. |

|

Minimal Chemical Usage |

Eco-friendly solution that minimizes chemical handling. |

|

Regulatory Compliance |

Helps businesses meet wastewater discharge standards. |

|

Reduced Sludge Volume |

Lowers sludge disposal costs and environmental impact. |

|

Low Maintenance Requirements |

Simple, durable design reduces maintenance costs. |

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt