Why Is a Filter Press Better Than Other Solid-Liquid Separation Equipment?

2025.10.13

2025.10.13

Industry News

Industry News

Introduction: The Need for Efficient Solid-Liquid Separation

In many industrial processes—such as mining, chemical production, wastewater treatment, and food processing—solid-liquid separation plays a crucial role. The goal is to remove solids from liquids efficiently, reduce waste volume, and recover reusable water or materials.

While there are several technologies available—such as centrifuges, belt filters, and vacuum filters—the filter press has become the preferred choice for many industries because of its efficiency, reliability, and low operating cost.

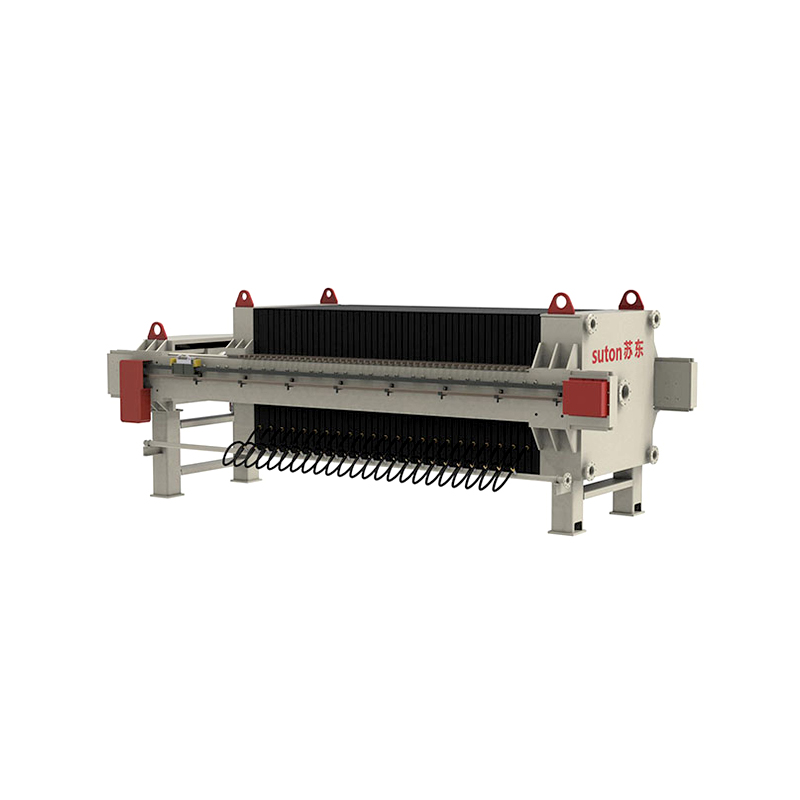

How Does a Filter Press Work?

A filter press operates on a simple but powerful principle: pressure-driven filtration.

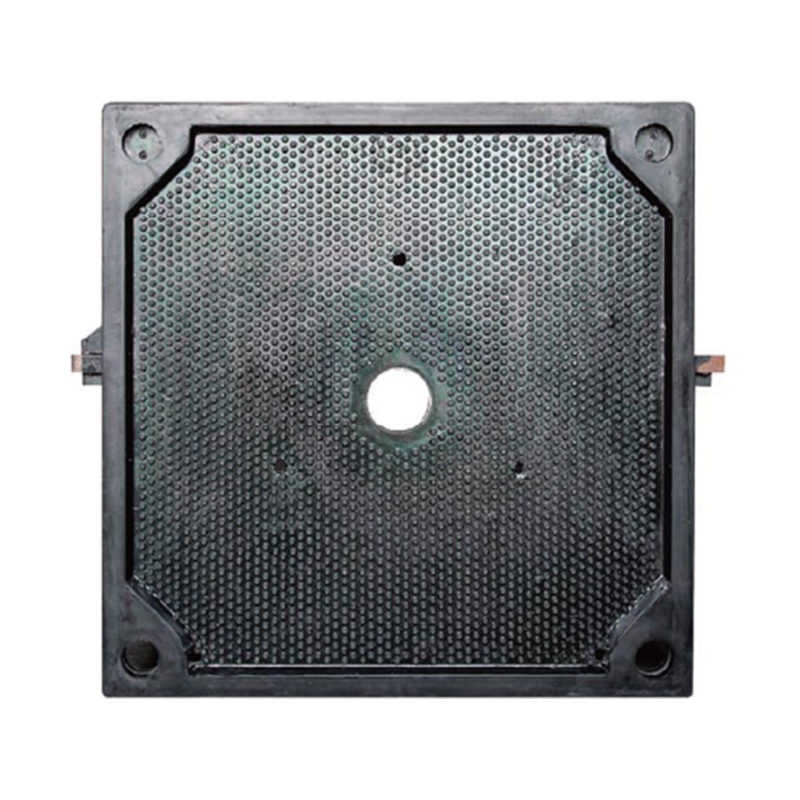

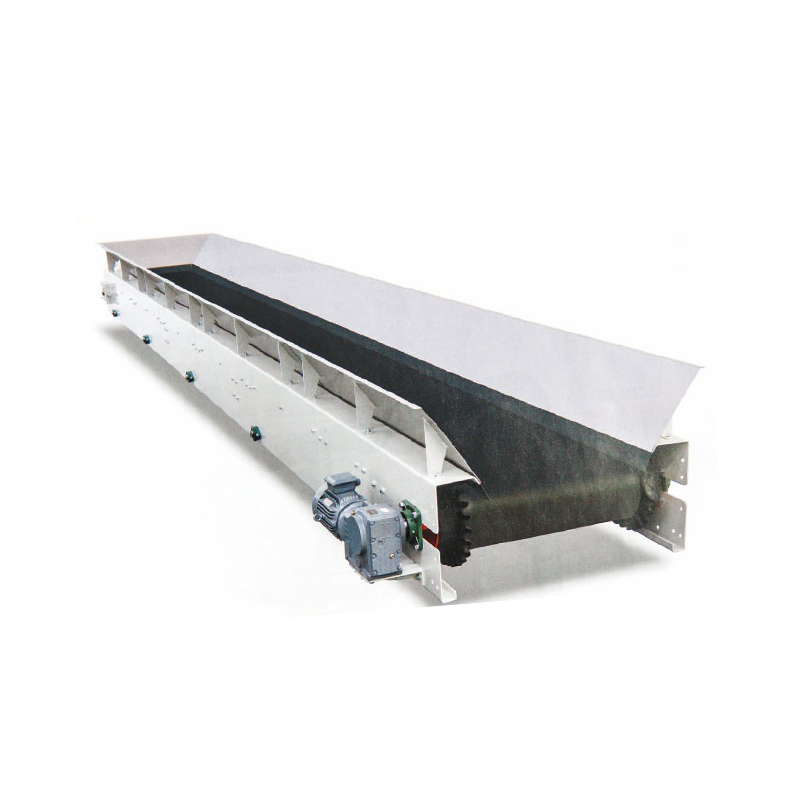

Slurry is pumped into a series of filter plates covered with filter cloths. When pressure builds up, liquid passes through the cloth, leaving solids trapped inside to form a “filter cake.” Once the filtration cycle is complete, the plates open, and the dry cake is discharged.

Depending on process requirements, filter presses can be manual, semi-automatic, or fully automatic, allowing flexible operation in both small-scale and large-scale systems.

Key Advantages of a Filter Press Over Other Separation Equipment

1. Superior Filtration Efficiency

Filter presses produce extremely dry filter cakes, often with a moisture content as low as 20–25%.

This is significantly lower than what most centrifuges or belt filters can achieve, which means less waste volume and lower disposal costs.

2. Lower Operating Costs

Unlike centrifuges that rely on high rotational speeds, a filter press uses hydraulic pressure to separate solids and liquids.

This results in lower energy consumption, fewer moving parts, and minimal wear and tear, which translates into reduced maintenance costs.

3. Higher Filtrate Quality

The filtrate from a filter press is clear and low in suspended solids, often reusable within the same process.

This makes it ideal for industries focusing on water recycling and zero-liquid-discharge (ZLD) systems.

4. Wide Material Compatibility

Filter presses can handle a wide variety of materials, including metal sludge, food waste, ceramic slurry, and industrial effluents.

Different filter cloth materials can be selected to match chemical resistance, particle size, and temperature requirements.

5. Long Service Life and Easy Maintenance

Because filter presses are mechanically simple, they are highly durable and easy to maintain.

Most parts are modular and can be replaced quickly, ensuring minimal downtime and extended equipment life.

Comparison: Filter Press vs. Other Separation Technologies

|

Feature |

Filter Press |

Centrifuge |

Belt Filter |

Vacuum Filter |

|

Cake Dryness |

⭐ High |

Medium |

Low |

Low |

|

Energy Consumption |

⭐ Low |

High |

Medium |

High |

|

Filtrate Clarity |

⭐ Excellent |

Good |

Moderate |

Moderate |

|

Maintenance |

⭐ Low |

Medium |

High |

Medium |

|

Investment Cost |

Medium |

High |

Low |

Medium |

As shown above, a filter press provides the best balance between performance, cost, and operational simplicity, making it a top choice for industrial applications.

When a Filter Press Might Not Be the Best Option

While the filter press is versatile, it’s not suitable for every scenario.

- High-volume continuous processesmay favor centrifuges for faster throughput.

- Oily or fine-particle slurriescan clog filter cloths, requiring frequent cleaning or special filter aids.

- Processes requiring continuous discharge(not batch-based) might be better served by belt filters.

Understanding these limitations helps engineers select the right equipment for their specific process needs.

Why the Filter Press Leads in Efficiency and Sustainability

In today’s industries, efficiency, energy saving, and sustainability are key performance indicators.

A filter press excels in all three areas—delivering drier solids, cleaner filtrate, and lower operating costs compared to other solid-liquid separation technologies.

For companies aiming to reduce waste disposal expenses, improve water reuse, or enhance environmental compliance, the filter press remains one of the smartest long-term investments in process equipment.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt