Why Is the Choice of Filter Press Plates Material Critical for Chemical Resistance?

2026.02.16

2026.02.16

Industry News

Industry News

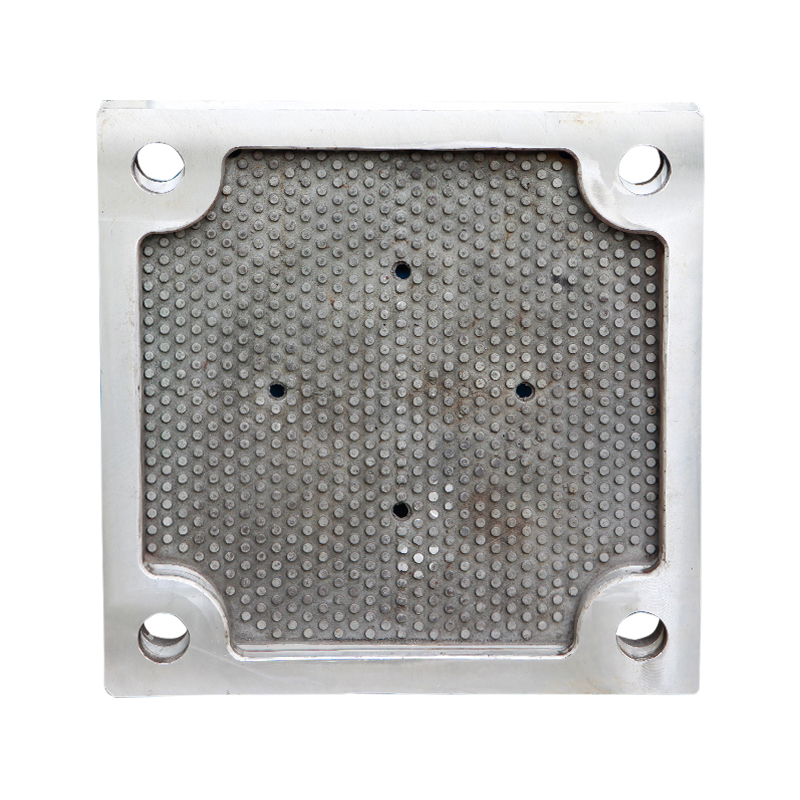

In the world of industrial filtration, filter press plates serve as the physical backbone of the entire separation process. While much attention is often paid to the feed pump’s pressure or the micron rating of the filter cloth, the material of the plates themselves frequently dictates the success or failure of long-term operations.

In chemically aggressive environments—ranging from acidic mining slurries to caustic pharmaceutical intermediates—choosing the wrong material is not just a minor oversight; it is a catalyst for catastrophic equipment failure, product contamination, and staggering downtime costs.

1. The Chemical Mechanism of Corrosion: Deep Roots of Plate Failure

Industrial slurries are rarely neutral; they often sit at extreme ends of the pH scale and are frequently accompanied by high abrasiveness or thermal fluctuations. When a filter press plate material is incompatible with the slurry, a series of complex physicochemical degradation processes occur, destroying the plate from the inside out.

- Chemical Leaching and Embrittlement:Under the influence of high-concentration organic solvents or strong oxidants, plasticizers or stabilizers within polymer plates (such as Polypropylene) can be leached out. This leads to the breaking of molecular chains, turning a once-tough plate into a brittle, glass-like state. Under hydraulic clamping forces reaching 15–20 bar, embrittled plates are highly susceptible to stress cracking or sudden explosive failure during the pressure cycle.

- Oxidation and Pitting:For metallic plates, strong acids or high-chloride environments trigger localized electrochemical reactions. This results in “pitting”—tiny holes that form on the sealing surface. These micro-voids expand rapidly, destroying the flatness of the plate edge. Once the sealing surface is compromised, the slurry “blows out” under pressure, causing material loss and corroding the main frame of the filter press.

- Thermal Softening and Synergistic Degradation:The corrosiveness of many chemicals increases exponentially as temperatures rise. A material that performs well at may lose its molecular stability, creep, or warp at in an acidic environment. Once a plate deforms, the sealing surfaces can no longer close perfectly, leading to severe lateral leakage.

Choosing a material with high chemical inertia ensures that the plates remain dimensionally stable and structurally sound under extreme conditions, maintaining the tight seal required for high-pressure filtration.

2. Core Material Comparison: PP, PVDF, and Stainless Steel

Different industries require different tiers of chemical defense. Selecting the “best” material depends entirely on your process’s chemical profile, including pH levels, temperatures, solvent concentrations, and the presence of abrasive particles.

- Reinforced Polypropylene (PP):This is the current industry standard. PP offers excellent resistance to most acids, alkalis, and inorganic salts. It is lightweight, cost-effective, and can be reinforced with glass fibers or mineral fillers to enhance its mechanical strength. However, its limitations lie in its poor resistance to strong oxidizers (like concentrated nitric acid) and specific organic solvents like benzene or toluene.

- PVDF (Polyvinylidene Fluoride):The “Gold Standard” for extreme environments. PVDF is virtually inert to almost all strong acids, oxidants, halogens, and organic solvents. In processes involving high temperatures (up to ) and intense chemical aggression, PVDF is often the only viable long-term solution. Despite its high initial cost, its superior stability results in a lower Total Cost of Ownership (TCO) in harsh conditions.

- Stainless Steel and Special Alloys:While stainless steel is susceptible to pitting from chlorides, it is the go-to for food-grade applications and high-temperature organic solvent filtration. In these scenarios, polymers might melt or leach contaminants. 316L provides good acid resistance, while higher-tier options like Hastelloy can handle extreme mineral acid environments.

3. Technical Comparison Table: Plate Materials and Chemical Compatibility

To assist engineers in rapid decision-making, the table below summarizes the technical boundaries of mainstream materials:

|

Material Type |

Recommended pH Range |

Max Operating Temperature |

Core Application Fields |

|

Standard Reinforced PP |

1 – 14 |

80°C |

Municipal wastewater, tailings, general pigments. |

|

High-Temp PP |

1 – 14 |

100°C |

Hot smelting slurries, high-temp chemical waste. |

|

PVDF |

0 – 12 |

130°C |

Strong oxidizers, ultra-pure chemicals, hydrometallurgy. |

|

Cast/Ductile Iron |

7 – 12 |

200°C |

Neutral oils, high-temp non-corrosive liquids. |

|

316L Stainless Steel |

2 – 10* |

250°C |

Edible oils, biopharma, organic solvents. |

4. The Economic Impact of “Wrong Material Selection”

Choosing a lower-grade material to save on Capital Expenditure (CAPEX) during the procurement phase often leads to an explosion in Operating Expenditure (OPEX) later on. This cost usually manifests in three ways:

- Product Purity and Contamination Risk:If a plate material degrades chemically, micro-plastics or metallic ions can leach into the filter cake or filtrate. In fine chemicals, pharmaceuticals, or the food industry, such contamination means the total loss of the batch, with damages potentially reaching millions of dollars.

- High Replacement Frequency and Downtime:In an incompatible environment, a PP plate may last only a few months instead of years. The cost of replacing a set of 50–100 plates involves not just the spare parts, but days of lost production and expensive labor for manual handling.

- Safety Liability and Legal Risks:Plates weakened by chemical corrosion act like time bombs under 15 bar of pressure. A bursting plate can spray hazardous chemicals onto operators, leading to severe corrosive injuries. The resulting safety investigations and legal costs far outweigh the premium paid for high-grade plates.

5. Filtration Engineering: Defense Beyond Raw Materials

Chemical resistance is not just about the raw resin; it also depends on surface engineering and integrated system solutions.

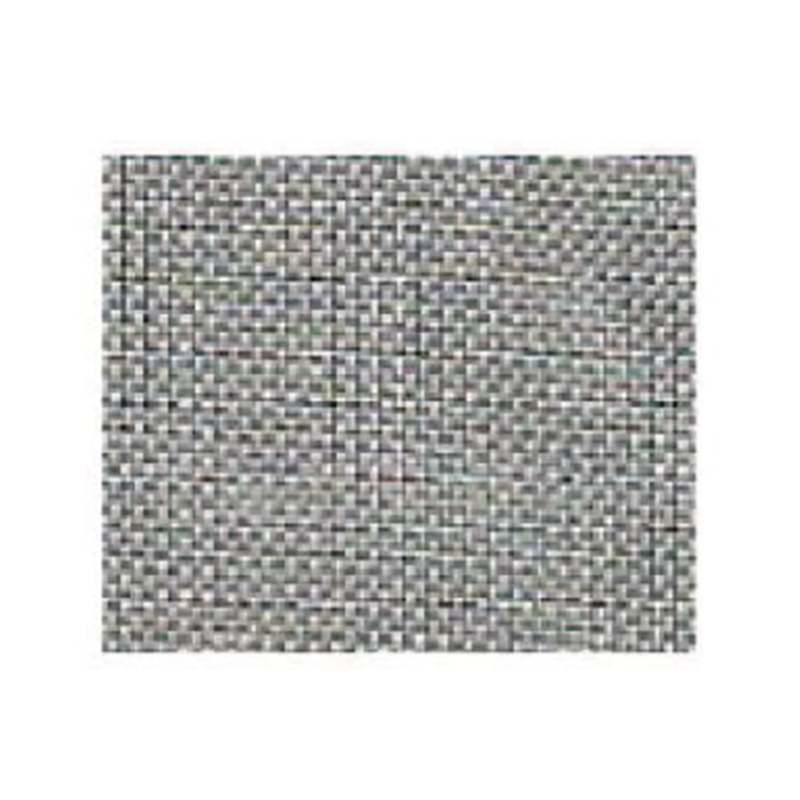

- Surface Finish and Release Performance:For sticky chemical cakes, a “mirror finish” on the plate surface reduces the chemical bonding force between the material and the plate. This allows the cake to drop more easily, reducing physical damage to the sealing surfaces caused by manual scraping.

- Membrane Squeezing and Wash Efficiency:In processes requiring cake washing, Membrane Plates allow for more thorough displacement washing. If the mother liquor is highly corrosive, removing it efficiently through membrane squeezing protects downstream piping and tanks from long-term corrosion.

- Gasketed Designs (CGR):For volatile or toxic chemicals, using plates with a “Caulked, Gasketed, and Recessed” (CGR) design ensures a “zero-leak” environment. This prevents corrosive vapors from escaping into the atmosphere, protecting external components and creating a safe environment for personnel.

FAQ: Frequently Asked Questions

Q1: How can I determine if my slurry is compatible with Polypropylene (PP)?

A: We strongly recommend a Chemical Compatibility Test. Submerge a sample of the plate material in your actual slurry at the operating temperature for 7–30 days. Observe the weight gain, swelling, or loss of hardness. If weight gain exceeds 2% or hardness drops by more than 10%, a higher-grade material should be considered.

Q2: Can I mix plates of different materials in the same filter press?

A: Generally, this is not recommended. Different materials (e.g., PP vs. Nylon) have different thermal expansion coefficients and compression moduli. During heating or pressure cycles, these differences lead to uneven stress, causing leaks or plate fractures.

Q3: Does the color of the PP plate affect its chemical resistance?

A: Usually, no. Colors (white, black, or blue) are typically pigment additives. However, black plates often contain carbon black, which improves UV stability (ideal for outdoor installations) and can offer slight reinforcement in specific organic environments.

References & Further Reading

- Corrosion Data Survey:Core standards regarding the stability of industrial polymers in various chemical media.

- ISO 19901-3:Petroleum and natural gas industries — Material selection and corrosion control.

- Chemical Engineering Progress (CEP):Research on the lifecycle of thermoplastic components in pressure filtration equipment.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt