Why Should You Choose a Chamber Filter Press for Your Filtration Needs?

2026.01.12

2026.01.12

Industry News

Industry News

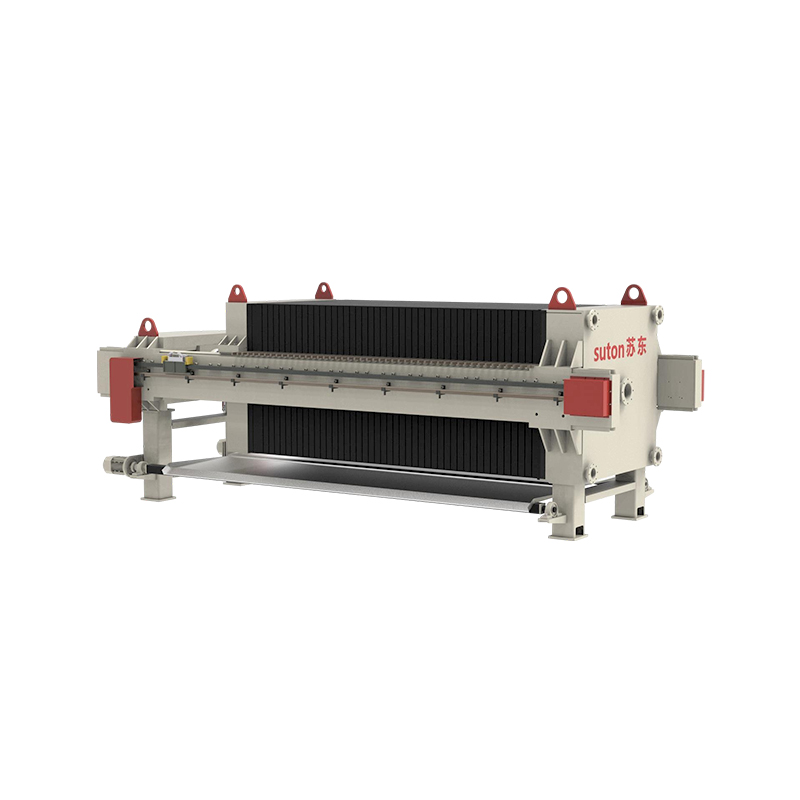

A Chamber Filter Press is one of the most efficient and reliable solutions for separating solids from liquids. It is a pressure-driven filtration technology commonly used in industries where effective solid-liquid separation is essential. The filter press uses a series of chambers to filter and separate the solids from the liquid phase. It’s particularly useful in applications such as wastewater treatment, mining, chemical processing, and food and beverage industries.

1. High Filtration Efficiency

Chamber Filter Presses are renowned for their high filtration efficiency. The system works by pressing a slurry between plates, where the liquid passes through a filter medium (cloth), leaving the solid particles behind. This process is done under high pressure, which forces the liquid through the filter cloth at a faster rate, leading to better separation. As the process continues, the solid particles form a thick “cake” that is trapped between the filter plates. The filtered liquid, now free of contaminants, is discharged, and the solid cake is removed for disposal.

The high pressure applied in a Chamber Filter Press leads to a significant reduction in moisture content within the cake. As a result, the filtered solids are usually drier than those produced by other filtration methods, such as vacuum filtration or centrifugal filtration. This is particularly beneficial when dealing with materials that need to be disposed of or recycled.

2. Cost-Effective

Although the initial cost of acquiring a Chamber Filter Press may be higher than some other filtration equipment, it delivers substantial cost savings over time. This is due to its high efficiency, low energy consumption, and minimal need for labor-intensive operations. The press’s design reduces downtime by allowing for automatic cycles, meaning it requires less human intervention.

Moreover, because the system can handle large volumes of slurry at once, you can process more material in a shorter period, which increases throughput. For businesses dealing with large volumes of waste or slurry, this feature can significantly reduce operational costs, improving overall profitability.

Additionally, since the filter press uses less water and fewer chemicals than some other filtration techniques, the long-term costs of consumables are also reduced. All of these factors contribute to making a Chamber Filter Press a highly cost-effective choice for industries where filtration is a regular and necessary part of production or waste management.

3. Customizable for Various Applications

One of the most notable advantages of a Chamber Filter Press is its versatility. The system can be customized to meet the specific filtration needs of different industries. Whether it’s handling chemical slurries in the chemical industry, wastewater in the environmental sector, or food waste in the food and beverage industry, Chamber Filter Presses can be tailored to accommodate the unique characteristics of the material being processed.

The filter press is available in different sizes, ranging from small bench-scale models to large industrial systems capable of handling several tons of slurry per day. The number and size of the chambers, as well as the pressure settings, can be adjusted depending on the desired filtration capacity and efficiency.

|

Feature |

Customization Options |

Application Suitability |

|

Chamber Size |

5 to 50+ chambers |

Suitable for both small and large scale operations |

|

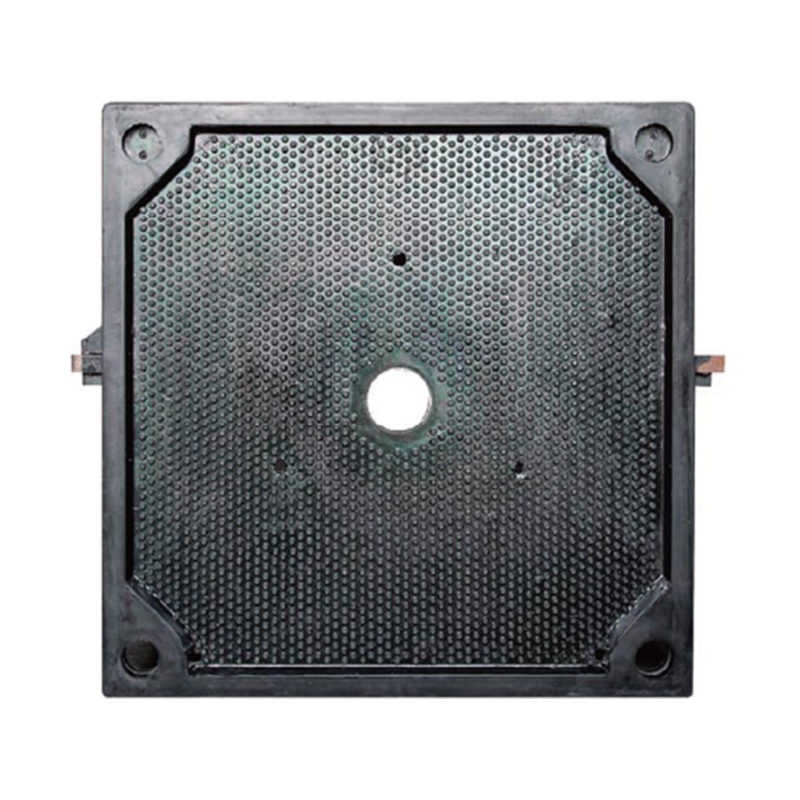

Plate Material |

PP, PVC, Stainless Steel |

Customizable depending on chemical resistance requirements |

|

Pressure Settings |

Adjustable up to 20 bar |

Allows adjustment based on slurry characteristics |

|

Filtration Media |

Cloth, Mesh, Synthetic Fabrics |

Custom media for specific types of slurries or chemicals |

These customizable features ensure that the Chamber Filter Press can be adapted to fit various needs, maximizing its performance and efficiency in different operational environments.

4. Minimal Chemical Usage

The Chamber Filter Press operates primarily through physical pressure rather than relying heavily on chemicals or additives. This is a significant advantage for industries where minimizing the use of chemicals is crucial. For example, in the food and beverage sector, reducing chemical additives is often a priority to ensure the safety and quality of the final product. Similarly, in wastewater treatment, reducing chemical usage helps to lower operational costs and minimize the environmental impact.

In traditional filtration methods, chemicals may be required to help separate solids from liquids, but the Chamber Filter Press’s high pressure can achieve the same result without the need for additional chemicals. This reduces both the financial and environmental costs associated with purchasing and disposing of chemicals, offering a cleaner, more sustainable filtration solution.

Moreover, using less chemical processing means that there is less risk of contaminating the environment or affecting the health of workers. This aligns with increasing environmental regulations and corporate sustainability initiatives that many industries are focusing on today.

5. Versatile Across Industries

Chamber Filter Presses are used in a wide range of industries, making them highly versatile. Whether it’s the food and beverage sector, mining, pharmaceuticals, or environmental services, the ability of the Chamber Filter Press to handle a variety of slurries makes it an ideal choice for many different applications.

For instance, in the mining industry, Chamber Filter Presses are essential for separating fine solids from water used in mineral processing. In wastewater treatment, they help remove contaminants and purify water before it is discharged back into the environment. Similarly, in the chemical industry, they assist in the separation of valuable by-products and waste materials.

The versatility of the Chamber Filter Press allows businesses to use it for different types of filtration processes, leading to higher adoption rates across multiple industries. This widespread applicability enhances its market value and ensures that businesses can rely on it for both specialized and general filtration tasks.

6. Improved Cake Disposal

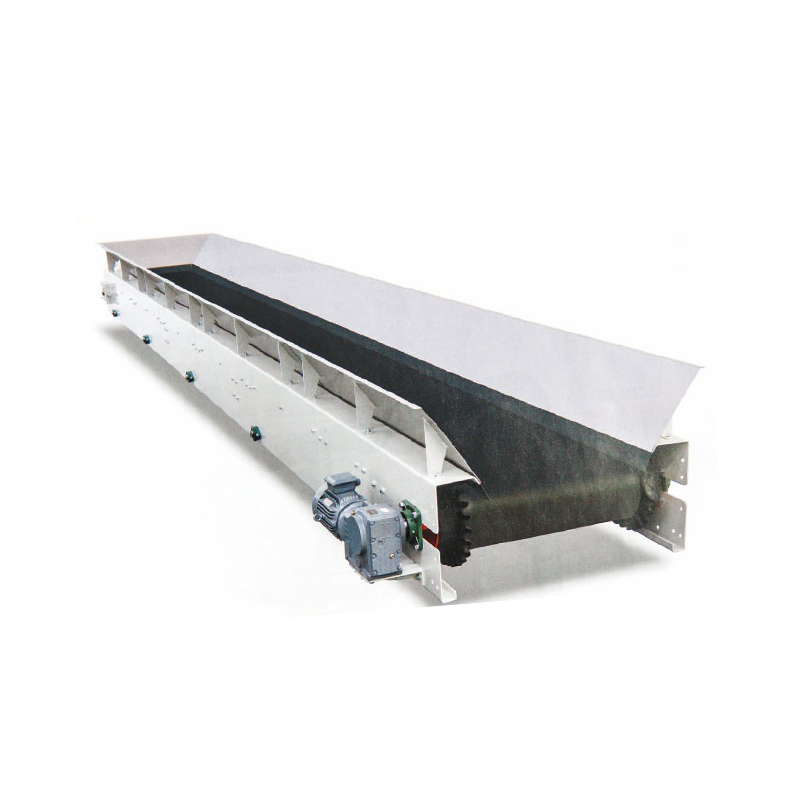

One of the key benefits of using a Chamber Filter Press is the quality of the solid cake that is produced. As the filtration process proceeds, the liquid phase passes through the filter cloth, leaving the solid particles to accumulate in the chambers. These solids, known as the “filter cake,” are typically drier and more compact compared to the cakes produced by other filtration methods.

The dryness of the filter cake simplifies its disposal. In many industries, the cake can be easily transported, handled, and disposed of without the need for additional drying or processing steps. Furthermore, the drier cake reduces the amount of space required for storage, which helps reduce waste disposal costs.

In some cases, the solid material collected in the filter cake can even be repurposed. For example, in mining, the filter cake may contain valuable minerals that can be extracted for further use or sale. In wastewater treatment, the solid cake may contain organic matter that can be processed further for use as compost or biogas production.

7. Durability and Reliability

Chamber Filter Presses are known for their durability and reliability. Built with robust materials like polypropylene or stainless steel, these filter presses are designed to withstand harsh operating conditions, including high-pressure cycles and exposure to abrasive or corrosive slurries.

The longevity of the Chamber Filter Press means fewer repairs and replacements, making it a solid investment for industries that rely on filtration processes. Regular maintenance, which is typically straightforward and easy to perform, can extend the service life of the equipment even further.

Additionally, the durability of the filter press reduces downtime and increases overall productivity. Businesses can depend on the filter press to operate efficiently day in and day out, ensuring a continuous production or waste treatment process.

8. Easy to Operate and Maintain

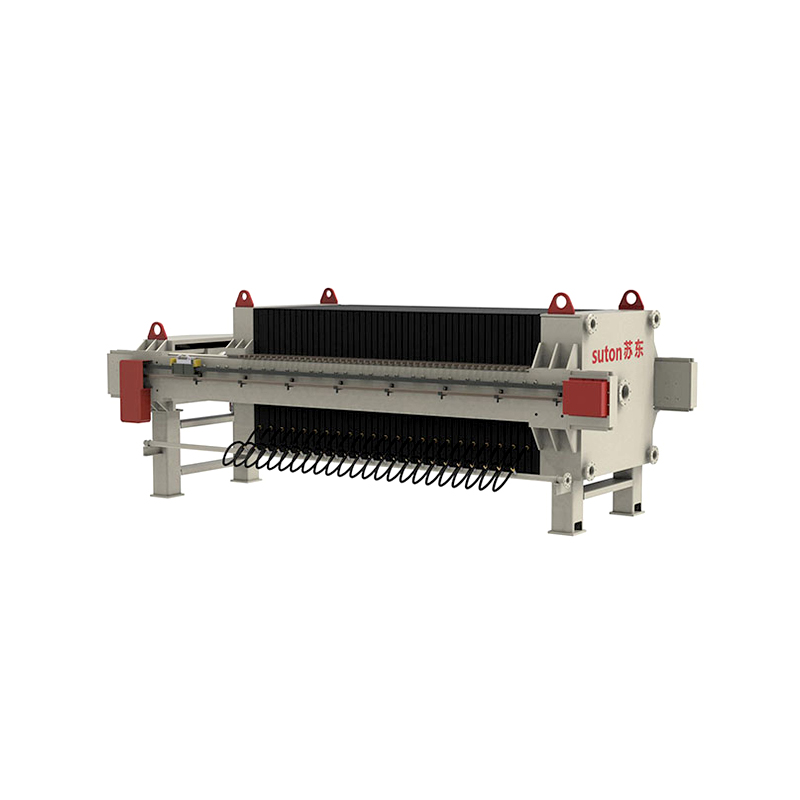

Chamber Filter Presses are designed for ease of use. Most models feature automated cycles that allow the press to operate without constant monitoring or manual intervention. This not only reduces labor costs but also minimizes the potential for human error.

Maintenance of the filter press is typically simple as well. The system is designed with easy access to key components, making it straightforward to clean, replace filter cloths, or perform routine inspections. Automated systems also provide real-time performance data, helping operators to detect issues early and schedule maintenance proactively, which helps to reduce unexpected downtime.

9. Environmentally Friendly

The environmental benefits of a Chamber Filter Press cannot be overlooked. By reducing the need for chemicals and minimizing waste production, the system is much more environmentally friendly than traditional filtration methods. The dry, compact filter cakes produced by the press are easier to dispose of or recycle, and the reduced water usage helps conserve valuable resources.

Additionally, industries are increasingly focusing on sustainability, and using a Chamber Filter Press is a step toward meeting environmental regulations and reducing a company’s carbon footprint. By offering a more efficient, eco-friendly solution for solid-liquid separation, the Chamber Filter Press supports a company’s commitment to sustainability.

10. Scalability

Chamber Filter Presses are easily scalable to accommodate growing business needs. Whether you need to process a small batch of material or large quantities, the system can be adjusted to handle a wide range of production levels. The press can be expanded by adding more plates and chambers, allowing for increased filtration capacity.

This scalability makes the Chamber Filter Press an excellent choice for businesses that anticipate growth or fluctuating filtration needs. As demand increases, the press can be easily upgraded, ensuring that your filtration system continues to meet your operational requirements over the long term.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt