Environmental protection equipment Application of efficient solid-liquid separation capability and versatility

Solid-liquid separation technology plays a vital role in industrial production, especially in industries involving large amounts of liquid waste. For dye wastewater, glue wastewater and other organic or inorganic wastewater that may be generated during the production process, they all need to be treated through effective solid-liquid separation technology to ensure that the production wastewater meets the discharge standards or is recycled and reused. This is not only a requirement to comply with environmental protection regulations, but also an inevitable choice to reduce production costs and improve resource utilization.

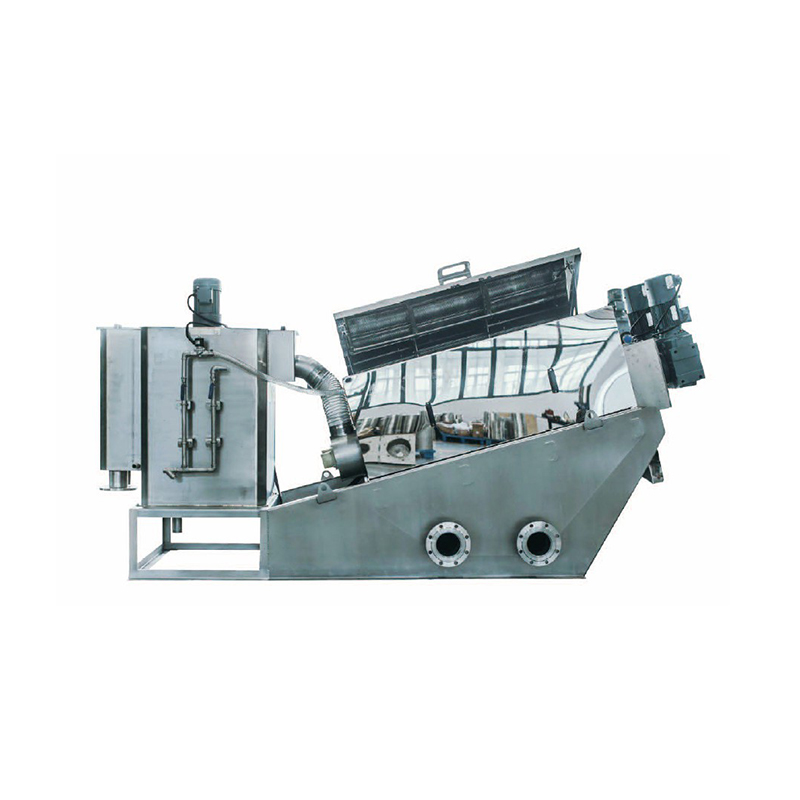

Environmental protection equipment uses high-pressure diaphragm pressing technology to further reduce the water content in the filter cake during the filter residue compression process, thereby increasing the solid recovery rate.

Reducing wastewater treatment costs: Through efficient solid-liquid separation technology, the reduction in moisture content in the filter residue means a reduction in wastewater treatment volume, thereby reducing energy consumption and chemical consumption for wastewater treatment, and directly reducing operating costs.

Improving resource recovery efficiency: During the production process, some solid wastes may contain valuable raw materials, such as pigment particles or other reusable chemicals. Efficient solid-liquid separation capabilities can maximize the recovery of these resources, reduce waste and improve resource utilization.

Ensure environmental compliance: Efficient solid-liquid separation technology can ensure the removal of solid particles in wastewater, avoid water pollution, and ensure that enterprises can meet increasingly stringent environmental emission standards.

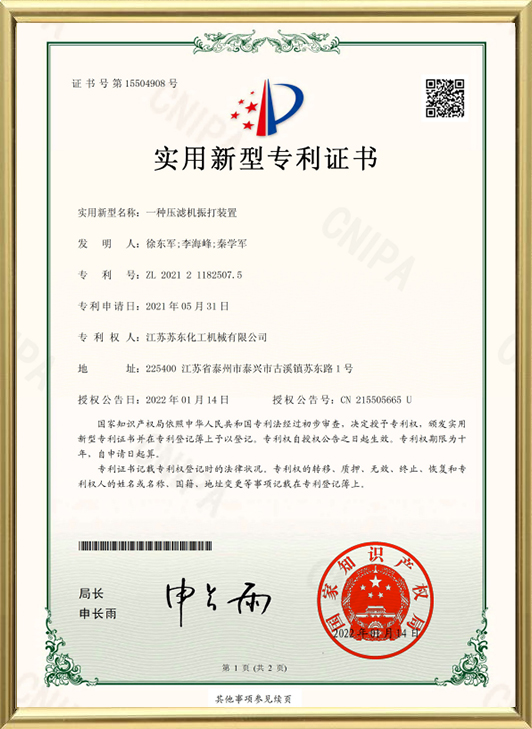

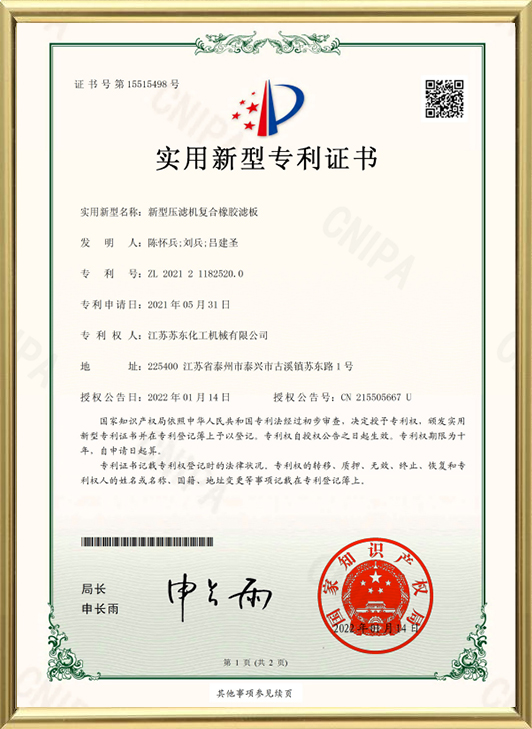

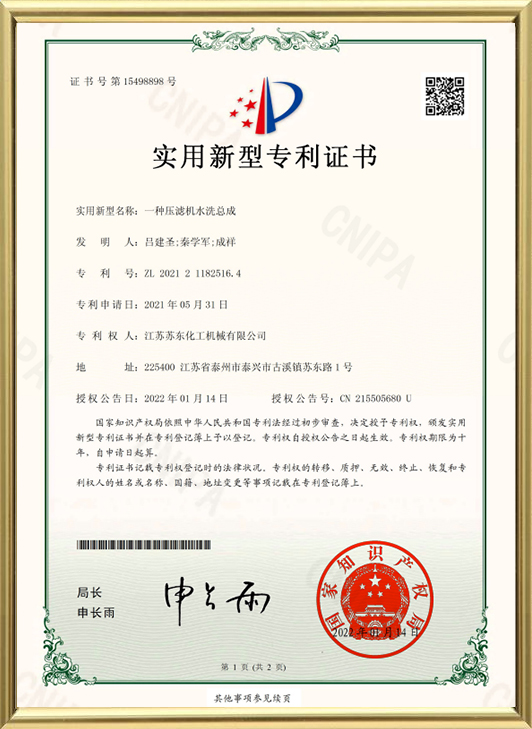

Jiangsu Sudong Chemical Machinery Co., Ltd.'s graphite-modified reinforced polyolefin composite filter plates have excellent corrosion resistance and high strength, and are particularly suitable for treating wastewater containing corrosive chemicals. This filter plate not only extends the service life of the equipment, but also reduces the frequency of filter plate replacement while maintaining efficient solid-liquid separation, thereby reducing equipment maintenance costs and downtime.

Versatility and industry adaptability of environmental protection equipment

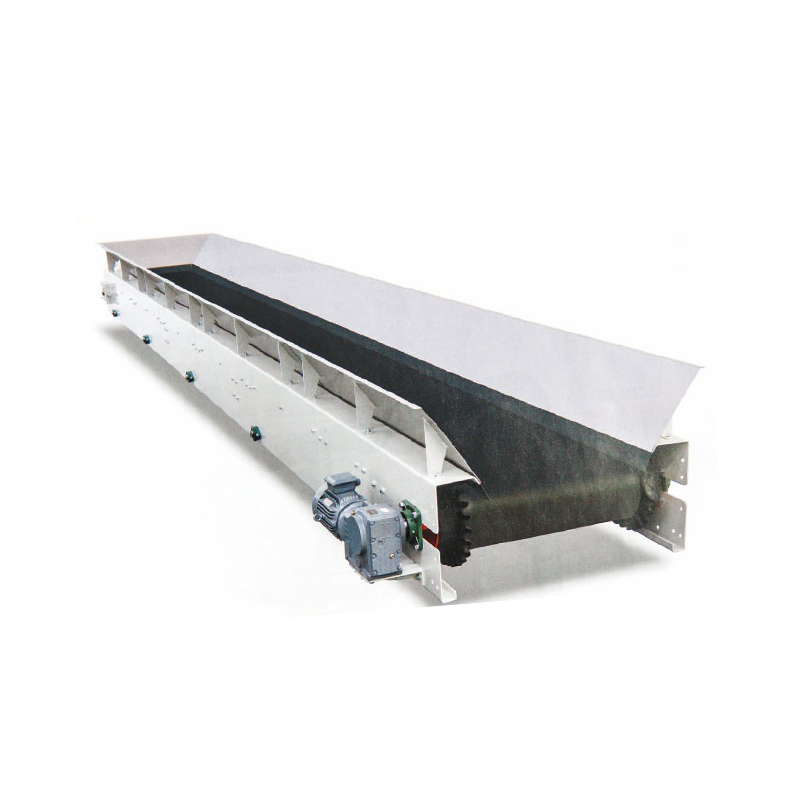

The versatility of environmental protection equipment refers to its ability to be flexibly applied in a variety of production environments, and can cope with different types of wastewater, solid waste and various complex treatment needs. The company can adapt to different types of production needs by replacing filter plates, adjusting pressing parameters, and configuring different automation modules.

Adapt to a variety of wastewater treatment needs: The wastewater generated during the production process may have different properties, such as dye wastewater, adhesive wastewater, and cleaning wastewater. Through modular design, Sudong filter press can select suitable filter plate materials and pressing methods according to the characteristics of different wastewater to ensure better treatment effects.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt