What role does the clamping device of the filter press play in the solid-liquid separation process?

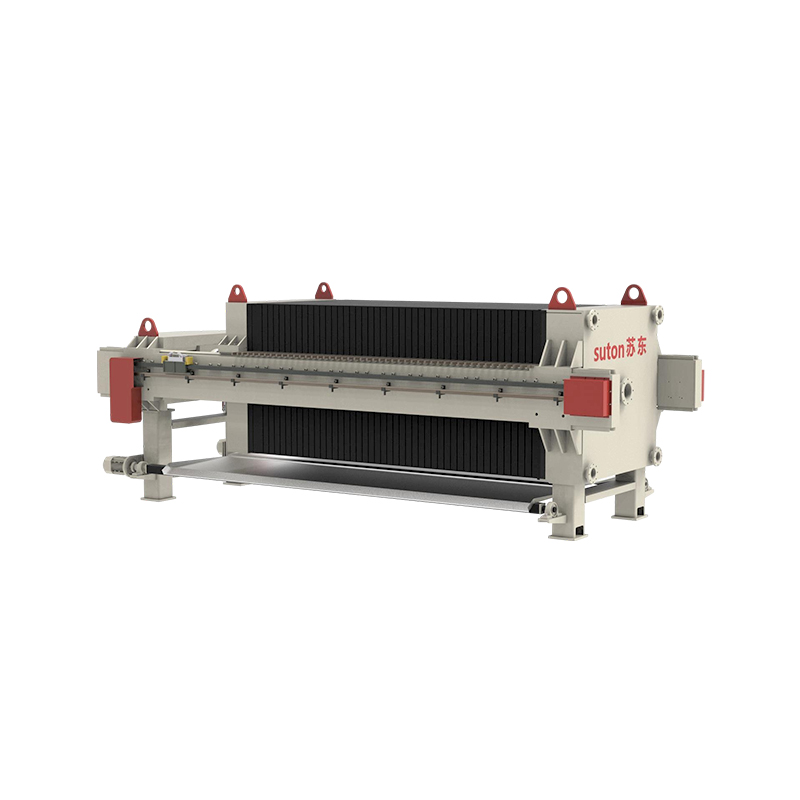

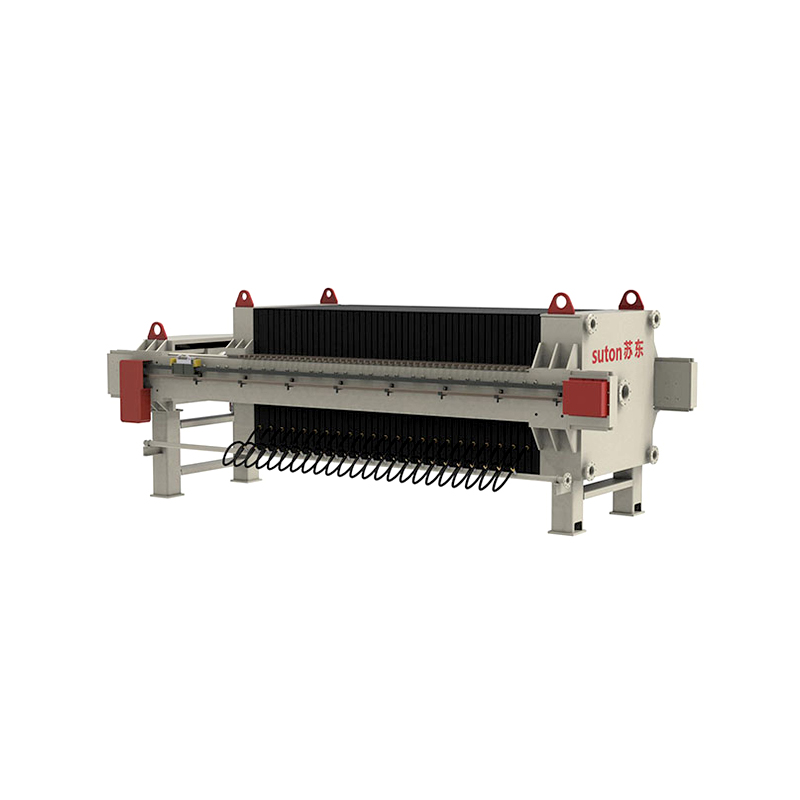

The clamping device of the filter press plays a vital role in the solid-liquid separation process. Its main function is to press the filter plates tightly together by applying strong pressure to form a closed filter chamber, thereby achieving effective solid-liquid separation. During the solid-liquid separation process, the material is pressed into the filter chamber, the liquid flows out through the filter cloth, and the solid particles are trapped on the filter cloth to form a filter cake. The stability and efficiency of the clamping device directly affect the sealing of the filter plate, the filtration efficiency and the moisture content of the filter cake. Therefore, as a professional enterprise in the manufacture of filter presses, we have strict requirements and attach great importance to the design, manufacture and quality control of the clamping device.

The design of the clamping device must take into account the uniformity and stability of the applied pressure. This pressure must be large enough to ensure a close fit between the filter plates to avoid leakage or leakage of the material during the filtration process. To this end, we use an advanced hydraulic clamping system that can apply uniform and controllable pressure on the filter plate and can be flexibly adjusted according to the different characteristics and process requirements of the material. Our hydraulic system design has been optimized many times, which can not only provide sufficient pressure, but also maintain long-term stability and reliability, avoiding the filtration effect affected by uneven or insufficient pressure.

Our company has more than 30 years of experience in filter press manufacturing and has accumulated rich technical reserves and production processes. We use high-strength steel to manufacture key components of the clamping device, and adopt advanced welding and processing technology to ensure that each clamping device has sufficient strength and durability. At the same time, our quality inspection department will conduct strict tests and inspections on each batch of clamping devices, including pressure tests, fatigue tests and durability tests, to ensure that it can still maintain excellent performance under high pressure conditions.

In terms of ensuring the stability and efficiency of the clamping device, the application of automatic control technology is also indispensable. Our company has introduced advanced PLC automatic control systems in R&D and manufacturing, which can monitor the operating status of the clamping device in real time and automatically adjust the pressure according to the setting of operating parameters. During the entire filtration process, the PLC system can ensure the continuous stability of the clamping pressure, and issue an alarm or make automatic adjustments in time when abnormal conditions are detected. This intelligent control greatly improves the convenience and safety of equipment operation.

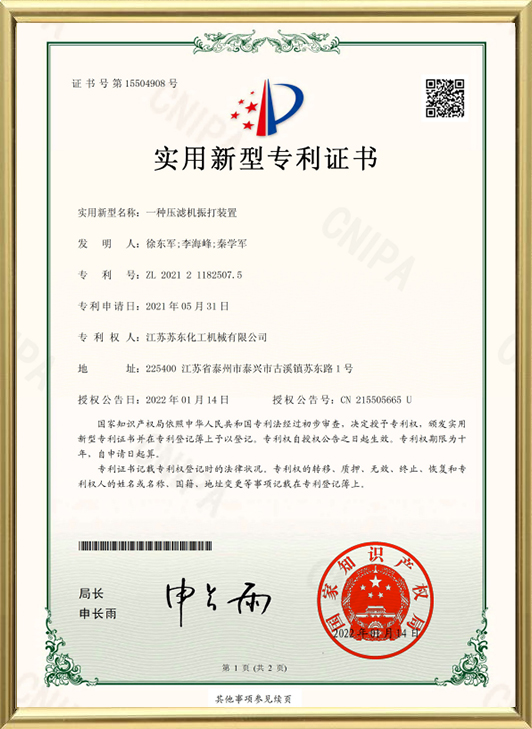

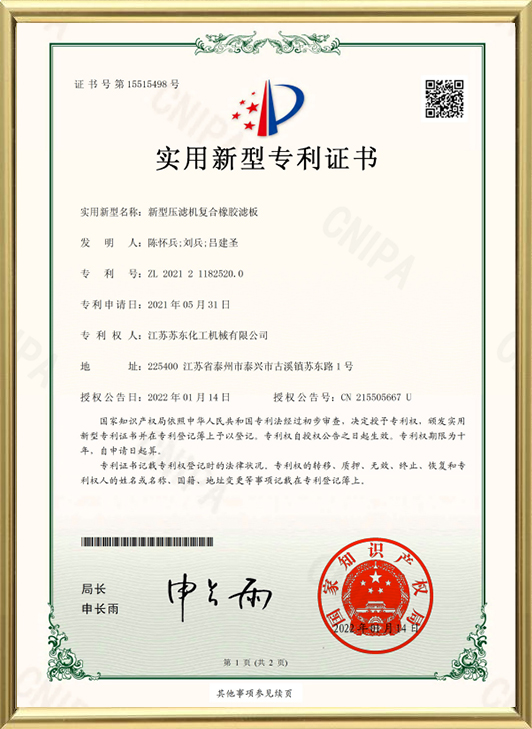

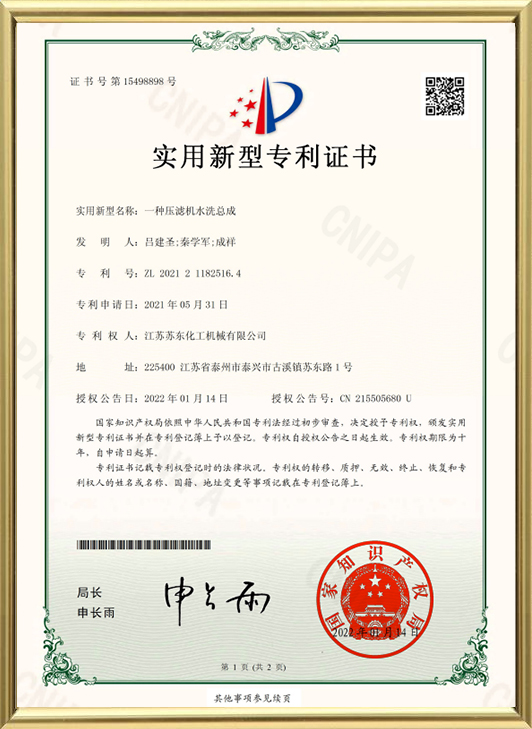

We have established long-term cooperative relationships with many universities and research institutions, especially in the innovative design and technical improvement of filter press clamping devices. Through simulation technology and test bench testing, we have conducted detailed research on various parameters of the clamping device, so as to continuously optimize its structural design and performance. We also hold a number of invention patents on clamping devices, which give our products a significant advantage in market competition. We are committed to applying the most advanced technology and the highest quality materials to the manufacturing process of each clamping device to ensure that it can show excellent stability and efficiency in practical applications. Through our meticulous manufacturing process, strict quality control system and continuous technological innovation, we can provide customers with filter press products with excellent performance and stable quality, helping customers achieve more efficient solid-liquid separation.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt